Containerized PSA Oxygen Generator(Cylinder Filling)

Bottled oxygen is gradually replaced by the oxygen produced by the oxygen generator due to the trouble of changing bottles and high cost. Jiangsu tai oxygen launched the filling and filling oxygen generator, which automatically fills and fills bottles with a full set of processes, with high oxygen purity, low cost and fast investment recovery.

Product Advantages

● The filling and bottle filling oxygen generator is more and more accepted by customers. It is safe and simple to operate, saves the trouble of manual bottle replacement, operates at full load for 24 hours, has fast investment recovery, low equipment noise and long service life. |

|

Provide clean raw air for the oxygen generator through the air purification component, ensure the adsorption efficiency and service life of molecular sieve.

The air storage tank assembly ensures the stable gas consumption of the system.

Oxygen buffer tank ensures stable gas supply to the system.

International famous brand valves (Burkert, Gumu, Germany) are selected, Japan (SMC, CKD, etc.) is a reliable guarantee for the stable operation of PSA equipment.

The unique pressing technology is a reliable guarantee for the service life of molecular sieve.

The pressing force is constant and does not change with the change of stroke.

The cylinder is equipped with indicator rod,which can directly measure the stroke.

With sinking alarm and limit shut down function.

The gas required by the cylinder is directly taken from the adsorption tower, which can work synchronously with the adsorption tower at any time.

Testing process in strict accordance with standards, ensure that each equipment leavingthe factory is safe, reliable and stable.

Oxygen generator diagram

Product Overview

This containerized oxygen system is basically a plug-and-play oxygen plant. Everything — the PSA oxygen generator, the air system, the booster, and the filling manifold — is already packed inside a standard container. You drop it on-site, hook up power, and you’re pretty much ready to start filling cylinders. No extra construction, no complicated setup.

Application Scenarios

People use this setup anywhere they need reliable on-site oxygen without building a full plant. Small hospitals, clinics, emergency projects, mining sites, fish farms, industrial workshops — anywhere that needs oxygen bottles on hand. It’s especially convenient for remote locations where oxygen delivery is a headache.

Technical Advantages

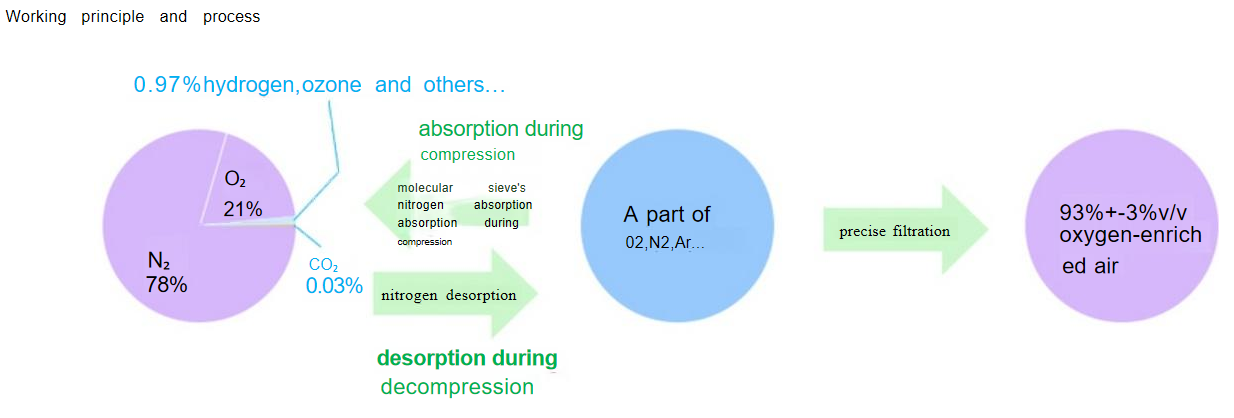

The oxygen generator runs on PSA technology, so purity stays steady and the system doesn’t need constant adjustments. The container keeps everything protected from weather, and the layout inside is neat: compressors, dryer, filters, oxygen generator, booster, filling ramp — all where they should be. The booster brings oxygen pressure up to cylinder-filling levels without stressing the system, and the whole thing is controlled automatically.

Quality Control

Before it ships out, the entire container is tested as a complete unit. We run the system, check oxygen purity, leak-test the filling lines, verify pressure stability, and simulate actual bottle filling. So when it arrives, you’re not troubleshooting — you’re producing oxygen from day one.

Service Advantages

If anything comes up, it’s usually easy to sort out. Most customers only need a quick video call. Spare parts are standard, and the system is built in a way that operators can do routine maintenance without special tools. The containerized design also means everything is organized and accessible — no crawling around machines to find valves.

Company Advantages

We’ve built a ton of these containerized units, so the design is well-proven. Because we handle the air system, PSA unit, and the filling setup ourselves, we control the quality from start to finish. Lead times are predictable, and the support stays consistent because you’re dealing with one team. It’s all about making oxygen production easy and dependable.