PSA Nitrogen Generator

Pressure swing adsorption (PSA) nitrogen generator is an automatic equipment which uses carbon molecular sieve as adsorbent and uses the principle of pressure adsorption and pressure reduction desorption to absorb oxygen from air, thus separating nitrogen.

Technical Parameters

| (Nitrogen Purity) HBFD97 nitrogen generator nitrogen purity: 97% | |||||

| Model | Nitrogen production | (Nm3/min) Effective air consumption | (DNmm) Inlet pipe size | (DNmm) Outlet pipe diameter | L*W*H (mm) Host |

| HBFD97-20 | 20 | 0.67 | DN15 | DN15 | 1250*600*1400 |

| HBFD 97-30 | 30 | 1.00 | DN 20 | DN15 | 1250*600*1850 |

| HBFD 97-40 | 40 | 1.33 | DN20 | DN25 | 1450 *700*1825 |

| HBFD 97-50 | 50 | 1.67 | DN25 | DN25 | 1150 *1130*1900 |

| HBFD 97-60 | 60 | 2.00 | DN25 | DN40 | 1150 *1130*1900 |

| HBFD 97-80 | 80 | 2.7 | DN32 | DN40 | 1750 *825*2090 |

| HBFD 97-100 | 100 | 3.3 | DN32 | DN40 | 1800 *850*2420 |

| HBFD 97-120 | 120 | 4.0 | DN40 | DN40 | 1800 *850 *2090 |

| HBFD 97-150 | 150 | 5.0 | DN40 | DN40 | 1850 *925 *2100 |

| HBFD 97-180 | 180 | 6.0 | DN50 | DN40 | 1850 *925*2390 |

| HBFD 97-200 | 200 | 6.7 | DN50 | DN40 | 2000 *950*2350 |

| HBFD 97-250 | 250 | 8.3 | DN50 | DN50 | 2100 *1000*2470 |

| HBFD 97-300 | 300 | 10.0 | DN65 | DN50 | 2100 *1100 *2530 |

| HBFD 97-350 | 350 | 11.7 | DN65 | DN50 | 2100 *1100*2800 |

| HBFD 97-400 | 400 | 13.3 | DN65 | DN80 | 2200 *1150 *2820 |

| HBFD 97-500 | 500 | 16.7 | DN80 | DN80 | 2350 *1400 *2870 |

| HBFD 97-600 | 600 | 20.0 | DN80 | DN80 | 2350 *1450 *3060 |

| HBFD 97-800 | 800 | 26.7 | DN100 | DN80 | 2500 *1500 *3480 |

| HBFD 97-1000 | 1000 | 33.3 | DN 100 | DN 100 | 2950 *1600 *3810 |

| HBFD 97-1500 | 1500 | 50.0 | DN125 | DN 100 | 2950 *1500 *4620 |

| HBFD 97-1800 | 1800 | 60.0 | DN125 | DN 100 | 2950 *1800 *4820 |

| HBFD 97-2000 | 2000 | 66.7 | DN125 | DN100 | 2950 *1800 *5020 |

| HBFD 97-2500 | 2500 | 83.3 | DN200 | DN100 | 5900 *1500 *4520 |

| HBFD 97-3000 | 3000 | 100.0 | DN250 | DN125 | 5900 *1500 *4620 |

(Nitrogen Purity) HBFD98 nitrogen generator nitrogen purity: 98% | |||||

| Model | Nitrogen production | (Nm3/min) Effective air consumption | (DNmm) Inlet pipe size | (DNmm) Outlet pipe diameter | L*W*H(mm) Host |

| HBFD98-15 | 15 | 0.55 | DN15 | DN15 | 1250*600*1400 |

| HBFD98-20 | 20 | 0.73 | DN 20 | DN15 | 1250 *600*1850 |

| HBFD98-30 | 30 | 1.10 | DN 20 | DN25 | 1450*700*1825 |

| HBFD98-50 | 50 | 1.83 | DN 25 | DN25 | 1150*1130*1900 |

| HBFD98-60 | 60 | 2.2 | DN25 | DN40 | 1650*800*2070 |

| HBFD98-80 | 80 | 2.9 | DN32 | DN40 | 1750 *825*2210 |

| HBFD98-100 | 100 | 3.7 | DN40 | DN40 | 1800*850*1940 |

| HBFD98-120 | 120 | 4.4 | DN40 | DN40 | 1800 *850*2090 |

| HBFD98-150 | 150 | 5.5 | DN40 | DN40 | 1850 *925*2240 |

| HBFD98-160 | 160 | 5.9 | DN50 | DN40 | 1850*925*2390 |

| HBFD98-180 | 180 | 6.6 | DN50 | DN40 | 2000*950*2350 |

| HBFD98-200 | 200 | 7.3 | DN50 | DN40 | 2000 *950*2450 |

| HBFD98-250 | 250 | 9.2 | DN50 | DN 50 | 2100 *1000*2660 |

| HBFD98-300 | 300 | 11.0 | DN65 | DN50 | 2100 *1100*2680 |

| HBFD98-350 | 350 | 12.8 | DN65 | DN50 | 2200 *1150*2720 |

| HBFD98-400 | 400 | 14.7 | DN65 | DN80 | 2250 *1200*2750 |

| HBFD98-450 | 450 | 16.5 | DN65 | DN80 | 2250 *1200 *2950 |

| HBFD98-500 | 500 | 18.3 | DN80 | DN80 | 2350 *1450*2870 |

| HBFD98-600 | 600 | 22.0 | DN80 | DN80 | 2350*1450*3160 |

| HBFD98-700 | 700 | 25.7 | DN 100 | DN80 | 2500 *1500*3330 |

| HBFD98-800 | 800 | 29.3 | DN 100 | DN 80 | 2600*1600*3610 |

| HBFD98-900 | 900 | 33.0 | DN 100 | DN80 | 2950*1600*3810 |

| HBFD98-1000 | 1000 | 36.7 | DN 100 | DN100 | 2950 *1500*4220 |

| HBFD98-1200 | 1200 | 44.0 | DN100 | DN 100 | 2950 *1600*4240 |

| HBFD98-1500 | 1500 | 55.0 | DN125 | DN100 | 2950*1600*4840 |

| HBFD98-1800 | 1800 | 66.0 | DN 125 | DN100 | 2950 *1800*5020 |

| HBFD98-2000 | 2000 | 73.3 | DN200 | DN100 | 5900 *1500*4220 |

| HBFD98-2500 | 2500 | 91.7 | DN200 | DN100 | 5900 *1600*4340 |

| HBFD98-3000 | 3000 | 110.0 | DN250 | DN125 | 5900 *1600*4840 |

Working Principle of Nitrogen Generator

Pressure Swing Adsorption (PSA) nitrogen generation is an advanced gas separation technology that uses high-quality, efficient carbon molecular sieves as adsorbents. It operates on the principle of pressure swing adsorption at ambient temperatures to separate air and produce nitrogen gas with a purity of 99.5%. This process is based on the principle of“high-pressure oxygen absorption and normal pressure oxygen release.”

The diffusion rates of oxygen and nitrogen molecules differ on the surface of the carbon molecular sieve. Smaller oxygen molecules (O2) diffuse faster and enter the micropores of the efficient carbon molecular sieve more readily, while larger nitrogen molecules (N2) diffuse more slowly and enter the micropores less frequently. This selective adsorption property of the carbon molecular sieve leads to the enrichment of oxygen in the adsorbed phase and nitrogen in the gas phase within a short time, enabling the separation of oxygen and nitrogen, ultimately resulting in the gas-phase enriched nitrogen under PSA conditions.

After a period of time, the adsorption of nitrogen reaches equilibrium. By lowering the pressure, the carbon molecular sieve releases the adsorbed oxygen, which is the regeneration process. Depending on the regeneration pressure, it can be classified into vacuum regeneration and normal pressure regeneration. Normal pressure regeneration facilitates thorough regeneration of the carbon molecular sieve, making it easier to obtain high-purity gas.

The PSA nitrogen generator is designed and manufactured based on pressure swing adsorption technology. Typically, it consists of two parallel adsorption towers controlled by a fully automated control system that strictly follows a specific programmable sequence, alternating between pressurized adsorption and depressurization regeneration to achieve nitrogen-oxygen separation and obtain the desired high-purity nitrogen gas.

The performance of the efficient carbon molecular sieve, particularly its dynamic adsorption capacity and separation factor, determines the quality of the nitrogen generator.

System flow description

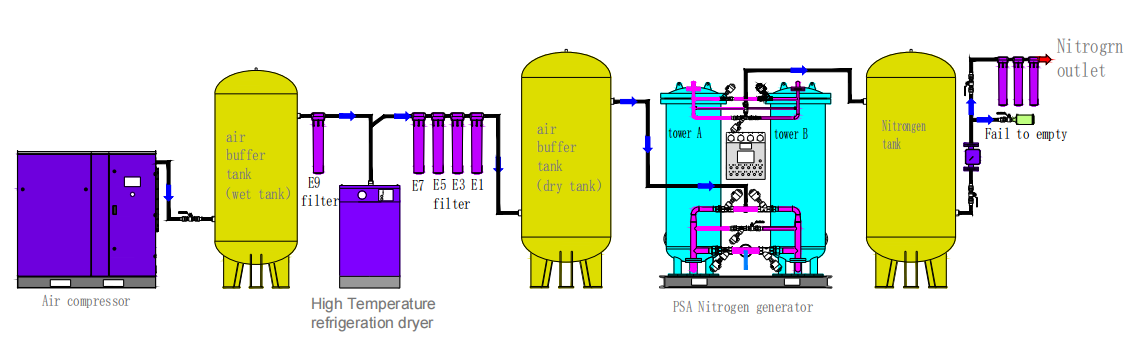

Air compressor → Air wet tank → C-class filter → Cold dryer →T/A/D class filter → mirco-heat regenerative adsorption dryer →T class filter → Air process tank (dry tank) →PSA nitrogen machine host → nitrogen process tank (unqualified empty, qualified output) → nitrogen storage pressure tank → nitrogen use site.

Advantages of Jiangsu Hongbo Gas Equipment Technology Co., Ltd. PSA Nitrogen Generator

High-Quality, Efficient Carbon Molecular Sieve

Selection : High-quality, efficient carbon molecular sieves are used to ensure maximum energy savings, lower power consumption, and reduced air waste ratio. The customized carbon molecular sieve from Hongbo Company features strong hardness, low powdering tendency, high nitrogen recovery rate, and long service life.The carbon molecular sieve is a crucial step in ensuring a low air waste ratio : According to the manufacturer's data, when the adsorption

pressure in the adsorption tower is 0.7MPa, the purity of nitrogen produced is 99.5%. After years of practical measurement and experimentation, our company designs a 10% reserve, with a waste ratio of 3:1 for 99.5% purity. The waste ratio is a key data point for determining the operational cost of the nitrogen generator—lower waste means lower electricity consumption for the air compressor and reduced operational costs.Lifespan : The carbon molecular sieve used by our company has the best capacity and stability in the country, with a lifespan of 8-10years.

Beijing Kunlun Tongtai Human-Machine Interface Touch Screen Control

The system flow diagram is displayed on the touch screen, showing real-time operation conditions of the nitrogen generator, gas flow direction, and more. The touch screen displays and records the accumulated operating time, alerting for maintenance after 8000 hours of operation. The reminder remains for 24 continuous hours but does not lead to automatic shutdown.The touch screen includes electronic manuals, circuit diagrams, flow charts,maintenance checklists, operating procedures, and fault alarms, all accessible for user inquiry.The equipment is equipped with four remote alarm signals : 1. Low inlet air pressure alarm ; 2. Low outlet nitrogen pressure alarm ; 3. High nitrogen purity, low alarm ; 4. High nitrogen dew point alarm ; 5. Unqualified nitrogen alarm. These signals can be displayed on the touch screen and transmitted remotely to the user's site, with PLC reserved communication interfaces for DCS, utilizing RS485 and MODBUS communication protocols.

Advanced Packing Technology Ensures Equipment Lifespan

The efficient carbon molecular sieve is packed using the “Blizzard ” method, ensuring uniform distribution without dead angles and minimizing powdering. he adsorption tower uses multi-stage airflow distribution equipment and automatic compression devices for the carbon molecular sieve, guaranteeing the adsorption performance and compression state, effectively extending the sieve's lifespan.Additionally, our uniquely designed extend-twist vibration platform packing method allows for denser and more uniform packing of the carbon molecular sieve, reducing friction to a minimum, ensuring no powdering during the adsorption process.

During the compression process, a vibration platform first ensures uniform compression of the carbon molecular sieve, followed by high-pressure air cannon for enhanced density and strength before installing the compression device.

Unique Structure of the Adsorption Tower

The bottom of the adsorber features a unique lotus-style airflow distributor, which avoids high-pressure airflow impact on the carbon molecular sieve, extending its lifespan. It also ensures uniform gas diffusion, greatly improving the efficiency and reducing energy consumption of the carbon molecular sieve.Inside the adsorption tower, special gas diffusion equipment allows compressed air to enter through a cyclone device, using specialized alumina ceramic balls (taking advantage of their spherical shape and hardness) to facilitate an “S ”-shaped gas flow before it contacts the activated carbon molecular sieve. This not only significantly reduces the impact on the carbon molecular sieve but also allows for more uniform gas adsorption, enhancing nitrogen generation efficiency and extending the sieve's lifespan.

Pneumatic Angle Seat Valves and Solenoid Valves

We use well-known pneumatic angle seat valves and imported solenoid valves with an opening time of 0.05 seconds and a normal service life exceeding 2 million cycles, characterized by simple structure, reliable sealing, rapid closure, and easy maintenance, ensuring reliable operation of oxygen generation equipment.

Siemens Intelligent Programmable Controller

Our nitrogen generator is equipped with a PLC (Programmable Logic Controller) control system from Siemens, which offers excellent controllability and a reasonable operational mode. It displays all operational parameters, statuses, and fault signals, automatically adjusting to load changes. The control system includes an LCD display control screen, which not only shows functions but also allows for flexible parameter settings and control. The dryer can achieve interlocking start-stop control with the air compressor, as well as remote control from a centralized control center, providing feedback on various status signals.The powerful features of the product enable complex control functions whether operating independently or as part of a network, resulting in a very high price-performance ratio. It excels in several aspects : extremely high reliability, a rich instruction set, convenient operation, extensive built-in integration features, strong communication capabilities, and diverse expansion modules.

Nitrogen Analyzer

Utilizes nitrogen analyzer produced by Shanghai Changai Electronics.

Automatic Exhaust Device for Unqualified Nitrogen

At the outlet of the nitrogen process tank, a nitrogen sampling port is set up for purity detection using the nitrogen analyzer. If the nitrogen purity is unqualified, the analyzer outputs a signal to control the pneumatic valve for discharging unqualified nitrogen into the atmosphere. When the nitrogen purity meets standards, the analyzer sends a signal to control the pneumatic valve to deliver qualified nitrogen to the user’s site.