Modular Oxygen Generator

Pressure Swing Adsorption (PSA) Oxygen Generation is an advanced gas separation technology. It uses high-quality, efficient oxygen-producing molecular sieves as the adsorbent and operates on the principle of pressure swing adsorption (PSA) at room temperature to separate air and produce high-purity oxygen at 93% ± 3%. The process follows the principle of adsorbing nitrogen under high pressure to generate oxygen, and desorbing nitrogen at normal pressure.

Product characteristics

| TYMKO-1400(TYMKO-1400 Aluminum Alloy Modular Oxygen Generator) | |||||||

| Model | Oxygen output (Nm3/h) | Air input pipe dia. | Oxygen input pipe dia. | Dimensions | 1400mm | Process tank | |

| 93% | L(mm) | W(mm) | H(mm) | ||||

| TY3-03 | 1.9 | DN15 | DN15 | 740 | 490 | 1705 | Internally installed |

| TY3-06 | 3.7 | DN15 | DN15 | 900 | 490 | 1705 | |

| TY3-09 | 5.5 | DN15 | DN15 | 1063 | 490 | 1705 | |

| TY3-12 | 7.4 | DN20 | DN15 | 1225 | 490 | 1705 | |

| TY3-15 | 9.3 | DN25 | DN15 | 1390 | 490 | 1705 | |

| TY3-18 | 11.1 | DN25 | DN15 | 1550 | 490 | 1705 | |

| TY3-21 | 13.0 | DN25 | DN15 | 1715 | 490 | 1705 | |

| TY3-24 | 14.8 | DN25 | DN15 | 1875 | 500 | 1705 | |

| TY3-27 | 16.7 | DN32 | DN20 | 2035 | 500 | 1705 | |

| TY3-30 | 18.5 | DN32 | DN20 | 2200 | 500 | 1705 | |

| TY4-20 | 18.5 | DN40 | DN20 | 1560 | 660 | 1705 | Extraposition |

| TY4-24 | 22.2 | DN40 | DN20 | 1720 | 660 | 1705 | |

| TY4-28 | 26.0 | DN40 | DN25 | 1885 | 660 | 1705 | |

| TY4-32 | 29.7 | DN40 | DN25 | 2045 | 660 | 1705 | |

| TY4-36 | 33.4 | DN40 | DN25 | 2210 | 660 | 1705 | |

| TY4-40 | 37.1 | DN40 | DN25 | 2370 | 660 | 1705 | |

| "TY3" represents 3 rows (including process tanks), "TY4" represents 4 rows (excluding process tanks) , "-03" represents 3 aluminum alloy towers. | |||||||

Working Principle of Modular Oxygen Generator

The pressure swing adsorption (PSA) oxygen generator is an automated device that uses zeolite molecular sieve as the adsorbent to adsorb and release nitrogen from the air based on the principle of high-pressure adsorption and low-pressure desorption, thereby separating oxygen. Zeolite molecular sieve is a white spherical granular adsorbent with micropores covered on its surface and inside, processed through a special pore-type treatment process. Its pore-type characteristics enable the kinetic separation of O2 and N2. The separation of O2 and N2 by zeolite molecular sieve is based on the slight difference in the kinetic diameters of these two gases: N2 molecules have a faster diffusion rate in the micropores of zeolite molecular sieve, while O2 molecules diffuse slowly. The diffusion rates of water and CO2 in compressed air are similar to that of nitrogen. Ultimately, oxygen molecules are enriched and produced from the adsorption tower. The pressure swing adsorption principle precisely utilizes the selective adsorption characteristics of zeolite molecular sieve and adopts a cycle of high-pressure adsorption (operation) and low-pressure desorption (regeneration), allowing compressed air to alternately enter the adsorption towers to achieve air separation and thus continuously produce high-purity oxygen products.

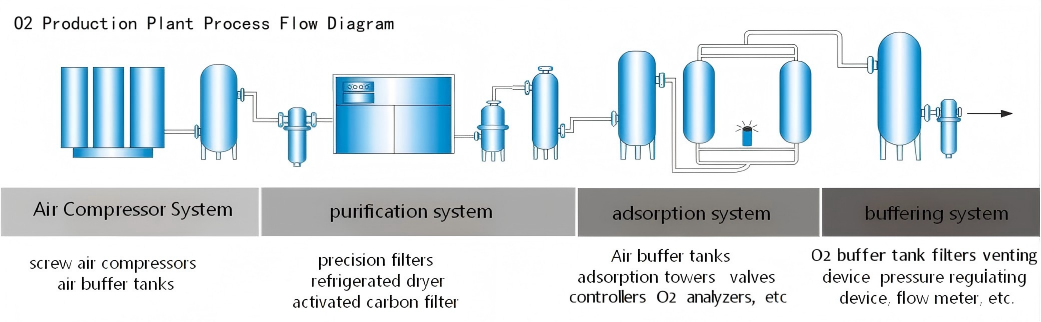

Process Flow Chart of Modular Oxygen Generator

Air Compressor → Air Moisture Tank → Primary Filter → Refrigerated Dryer → Secondary Filter → Tertiary Filter → Quaternary Filter → Quinary Filter → Air Dry Tank → PSA Aluminum Alloy Modular Oxygen Generator → Oxygen Storage Tank → Oxygen Analyzer → Flow Meter → Gas Usage Point

Requirements of Modular Oxygen Generator Main Unit for Compressed Air

Item | Requirement |

Pressure | ≥ 0.6MPa, ≤ 0.7MPa |

Residual Oil Content | ≤ 0.001ppm |

Mechanical Impurities | ≤ 0.1 μm |

Pressure Dew Point | ≤ 8℃ |

Structure of Modular Oxygen Generator

It generally consists of three parts: modular adsorption barrels, pipeline valves and electric control cabinet. Specifically, it includes chassis, air buffer tank, oxygen storage tank, aluminum alloy adsorption cylinders, zeolite molecular sieves, gas distribution systems, compression devices; valves such as pneumatic valves, solenoid valves, check valves, filter pressure reducing valves; instruments and meters such as PLC controllers, high-efficiency silencers, oxygen analyzers, flow meters, pressure gauges; and accessories such as connecting pipelines.

Advantages of Modular Oxygen Generator

1. Low equipment cost and strong portability: Adopting a PSA aluminum alloy modular design, the device is a new type of high-tech equipment. The aluminum alloy material not only reduces the manufacturing cost, but also greatly reduces the equipment volume and weight, facilitating transportation, installation and flexible placement. It is suitable for use in various venues and does not require excessive space.

2. Easy operation and maintenance: The equipment features a simple and understandable operation process, which can be quickly mastered by ordinary staff without complex training for professional technicians. The daily maintenance difficulty is low, only requiring regular inspection of basic components without tedious maintenance procedures, effectively saving labor and time costs.

3. Low operating cost and easily available raw materials: The raw material for oxygen production is directly taken from natural air, eliminating the need for additional purchase and storage of special raw materials and saving raw material costs. During operation, only stable compressed air and power supply are required without other complex auxiliary equipment, greatly reducing the overall operating costs.

4. High degree of automation and fast oxygen production speed: The equipment adopts full automatic control, enabling unattended operation and reducing the cost of manual on-duty. Qualified oxygen can be produced within 10-30 minutes after the first startup, and the standard can be reached within only 3-10 minutes for the second startup, which can quickly meet the oxygen production demand.

5. Green and pollution-free: No chemical reagents are added during the entire oxygen production process, and no pollutants such as wastewater, waste gas and waste residue are discharged. It meets the requirements of modern environmental protection production and use, and is safe and environmentally friendly in the use process.

Application Fields of Modular Oxygen Generator

1. Ozone generation field: The equipment produces oxygen with stable purity, which can be used as a high-quality raw material for ozone generation, adapts to the process requirements of ozone production, and provides efficient and reliable gas source support for ozone generation.

2. Aquaculture field: It can supplement sufficient oxygen to aquaculture water, improve the water environment, ensure the normal respiration of aquatic animals, help improve the survival rate of aquaculture, and adapt to the oxygen supply needs of various aquaculture scenarios.

3. Aerospace field: Relying on the advantages of stable operation, small volume and fast oxygen production, it can meet the emergency or regular oxygen supply needs in aerospace-related scenarios and adapt to the special use environment of aerospace equipment.

4. Medical and health care field: It can provide oxygen that meets the standards for daily health care oxygen inhalation and relief of mild hypoxia symptoms. The equipment is safe and reliable, and can meet the basic oxygen supply needs in the medical and health care field.

Notes

Due to structural limitations, the oxygen purity of the equipment can reach 93%±3% with a maximum flow rate of 40Nm³/H; the secondary purification for high-purity oxygen production has no price advantage, so it is not recommended to select the 99% purity model. In addition, the application fields are expanded reasonably in combination with our company's design capabilities.