PSA Oxygen Generator

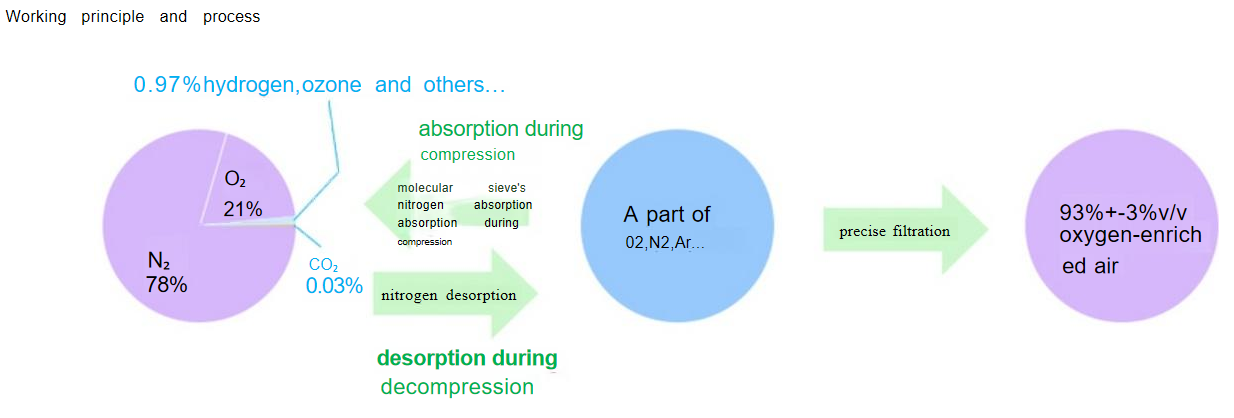

PSA oxygen generator is a fully automatic equipment for directly producing oxygen from compressed air by using the zeolite molecular sieve as an adsorbent, utilizing the adsorption capacity of oxygen and nitrogen difference on the molecular sieve surface through the principle of pressure adsorption and declining pressure desorption.

Technical indicators

|  |

Technical Parameters

| Model | (Nm³/h) Gas production | (Nm³/min) air consumption | DN(mm) Imported nominal diameter DN | DN(mm) Imported nominal diameter DN | Air nominal diameter DN | L * W * H ( m m ) Host |

| HBF093-1 | 1 | 0.2 | DN15 | DN15 | BL0010 | 800*650*1720 |

| HBF093-2 | 2 | 0.4 | DN15 | DN15 | BL0010 | 950*950*1500 |

| HBF093-3 | 3 | 0.6 | DN15 | DN15 | BL0010 | 1050*900*1865 |

| HBF093-5 | 5 | 1 | DN20 | DN15 | BL0010 | 1450*900*1825 |

| HBF093-10 | 10 | 2 | DN32 | DN15 | BL0020 | 1450*900*1825 |

| HBF093-15 | 15 | 3 | DN40 | DN25 | HBHAD-4-0 | 1800*950*1940 |

| HBF093-20 | 20 | 4 | DN40 | DN25 | HBHAD-6-0 | 1850*1025*2100 |

| HBF093-25 | 25 | 5 | DN50 | DN25 | HBHAD-6-0 | 2000*1050*2210 |

| HBF093-30 | 30 | 6 | DN50 | DN25 | HBHAD-8-0 | 2000*1050*2530 |

| HBF093-50 | 50 | 10 | DN65 | DN25 | HBHAD-13-0 | 2200*1250*2720 |

| HBF093-60 | 60 | 12 | DN65 | DN40 | HBHAD-15-0 | 2250*1300*2850 |

| HBF093-80 | 80 | 16 | DN80 | DN40 | HBHAD-20-0 | 2350*1550*3060 |

| HBF093-100 | 100 | 20 | DN100 | DN40 | HBHAD-25-0 | 2500*1600*3330 |

| HBF093-120 | 120 | 24 | DN100 | DN40 | HBHAD-30-0 | 2600*1700*3670 |

| HBF093-150 | 150 | 30 | DN150 | DN40 | HBHAD-40-0 | 4700*1500*2980 |

| HBF093-180 | 180 | 36 | DN200 | DN40 | HBHAD-40-0 | 4700*1600*3370 |

| HBF093-200 | 200 | 40 | DN200 | DN40 | HBHAD-60-0 | 5000*1600*3330 |

| HBF093-240 | 240 | 48 | DN200 | DN50 | HBHAD-60-0 | 5200*1700*3670 |

| HBF093-300 | 300 | 60 | DN250 | DN50 | HBHAD-80-0 | 5900*1600*4520 |

Oxygen generator diagram

Industrial Oxygen Generators: Key Applications, Selection Criteria & Operational Guidelines

· Metal Fabrication & Welding:Oxygen is a must for oxy-fuel cutting, welding, and brazing. Pick the right purity, and you’ll notice better flame temperature and faster cutting in steel shops and manufacturing plants.

· Water & Wastewater Treatment: Oxygen injection is the key factor that makes biotreatments very effective, also it accelerates the oxidative processes, and it is very helpful in aerobic digestion; all these are valid whether we are talking about city or industrial wastewater plants.

· Glass Manufacturing: Oxygen addition to glass melting furnaces improves the combustion efficiency, reduces NOx emissions, enhances melting quality, and is capable of cutting the fuel consumption by 20-40% (these figures represent the typical usage of these types of generators in the industry).

· Pulp & Paper Industry: Employing oxygen in delignification and bleaching stages reduces the use of chemicals, lessens pollution, and improves paper quality in pulp mills.

· Chemical & Petrochemical Production: The device is basically required in oxidation reactions, catalyst regeneration, and combustion intensification in a plant producing ethylene, methanol, and other chemicals.

· Aquaculture & Fish Farming: Oxygen apparatus can maintain the dissolved oxygen level in fish tanks, hatcheries, as well as in the transport of fingerlings. The takeaway is that if a reasonable fish density is kept, the fish will remain healthier.

How to Pick the Right Purity & Flow Rate

Knowing the right oxygen purity and flow is very important not only for a smooth process but also for saving money. Our technical team has a simple method to help you make a choice:

Oxygen Purity Tips:

· 90-93% Purity: Is suitable for combustion reinforcement, wastewater treatment, and aquaculture. Moderate oxygen enrichment provides you with real advantages without incurring too high a cost.

· 93-95% Purity: It is enough for the majority of metal cutting/welding, glass manufacturing, and chemical processes on the basic level. It is a good balance between performance and operating costs.

· 95-99% Purity: It is a requirement for welding that is highly specialized, some chemical oxidation processes, and advanced wastewater treatments – where oxygen plays an extreme role to obtain the final result.

· 99%+ Purity: It is a necessity for processes related to pharmaceuticals, high-accuracy laser cutting, and specialized laboratory processes. Just to let you know: typically going beyond 99% purity requires additional purification stages and both the initial and the running costs are higher.

Flow Rate Calculation:

· Before anything else, add up all the oxygen consumptions that are done at the same time, and then, for a future growth, put a 15-20% safety margin—this is your maximum demand.

· You should also take into account fixed, daily and occasional, short periods of high demand while making a decision on the equipment size.

· Figure out whether a single large generator will be able to do the job better or if it is good to have a few smaller, modular units—this largely depends on how the oxygen requirements in your plant change.

· Do not forget about altitude: for every 1,000 feet above sea level, the capacity of oxygen generation is reduced by approximately 3% (this is according to common technical specifications).

Installation & Site Prep:

· The ventilation of the generator room should be such that it keeps the oxygen levels below 23.5% (this is in accordance with safety standards).

· Install oxygen sensors in closed areas where the generator is operating.

· Use air that is clean, dry, and oil-free, and properly filtered (0.01-micron coalescing filters are suggested for optimum results).

· The temperature of the room should be kept from 40°F (4°C) to 115°F (46°C) if the adsorption is to be continuous and stable.

· Leave at least 3 feet/1 meter of space around the equipment—this is standard for maintenance.

Maintenance Needs:

· Replace inlet air filters every 2,000-4,000 operating hours—depends on how clean the air is at your site.

· Check and replace molecular sieve material every 5-10 years, based on how you’re using the equipment.

· Inspect valve assemblies every 6-12 months to make sure they’re working properly.

· Oxygen purity sensors should be calibrated one time every year in order to maintain accurate readings.

·It is very good for you to keep proper maintenance records: note down the purity readings, the flow rates, and the time when you changed the parts.

Saving Energy:

· Put variable frequency drives (VFDs) on compressors so the power matches the amount of oxygen you require.

· If your plant requires thermal energy, why not installing heat recovery systems?

· Install automated controls that enable the equipment to idle or shut down when the demand is low.

· Frequently measure the system's efficiency as compared to your baseline figures.

Following Regulations:

· Conform to OSHA 29 CFR 1910.104 (rules for the storage and handling of oxygen) strictly.

· In case of medical-related uses, refer to NFPA 99 (Healthcare Facilities) guidelines.

· Comply with the local building codes when setting up the oxygen generator.

· Keep all necessary documents for insurance and regulatory inspections.

ABOUT US

Hongbo integrates R&D, design, and production, covering an area of 15,000 m², with a workshop area of 8,000 m².

Hongbo currently employs over 150 people, including 16 engineers and 18 after-sales service staff. Among them are 3 senior engineers, 2 with master’s degrees, 11 with bachelor’s degrees, and 30 with associate degrees — forming a strong foundation for standardized mass production of Hongbo products.

The company attaches great importance to technological innovation and intellectual property protection. To date, it has obtained 1 invention patent, 21 utility model patents, and 3 software copyright certificates, among other achievements.

Over the past 16 years, Hongbo’s industrial gas equipment — known for its advanced technology, superior quality, reasonable pricing, and outstanding after-sales service — has been widely applied across key industries including chemical fiber, pharmaceuticals, environmental protection, electronics, lithium batteries, new energy, food preservation, steel, powder metallurgy, heat treatment, petrochemicals, offshore oil development, warehousing and shipping, and national defense aerospace.

FAQ

1.Why customer choose us?

Jiangsu Hongbo Gas Equipment Technology Group Co, Ltd. is a professional manufacturer for green gas plant, We have more than 20 years experience in producing and exporting those machines and spare parts.

2.What's your delivery time?

Generally 10-45 days, if urgently order, pls contact our sales in advance.

3.What's payment term?

T/T, L/C, Paypal and etc. Also we could accept USD, RMB, Euro and other currency (Pls contact our sales for more information

4.How about your after-sales service?

1. Provide customers with installation and commissioning online instructions. 2. Well-trained engineers available to overseas service 3. World wide agents and after service available

5. What is the typical oxygen purity?

Most PSA oxygen generators provide 90%–95% oxygen purity. Purity can be customized depending on model, flow rate, and application requirements.

6. How long does a PSA oxygen generator last?

With proper maintenance, the equipment can operate 8–10 years or more. Molecular sieve typically lasts 5–8 years, depending on air quality and operating conditions.

7. Can the system run 24/7?

Yes. PSA oxygen generators are designed for continuous, round-the-clock operation and automatic switching between adsorption towers.

8. What flow rate models are available?

Typical flow rates range from 1 L/min to 500 Nm³/h or customized according to the customer’s project.