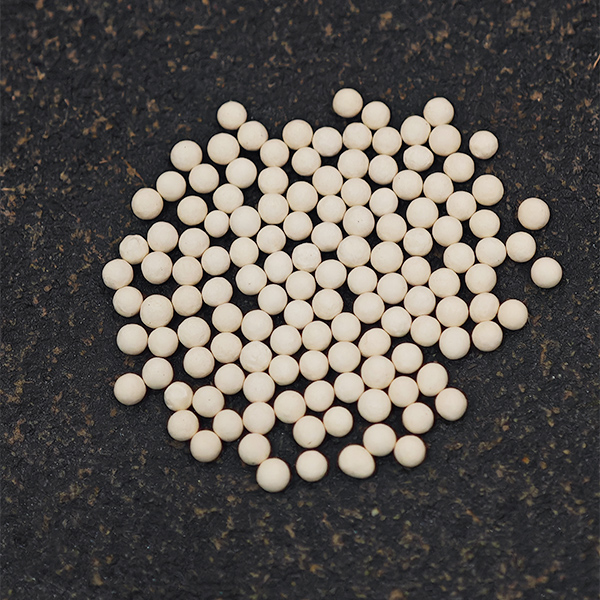

Diameter 0.4-0.8mm Carbon 3A/4A/5A Adsorbent Oxygen Psa Zeolite Molecular Sieve Maily Used in Psa Oxygen Adsorbent

Product Introduction

3A High-Strength Molecular Sieve has a pore size of 3Å and can adsorb molecules with a critical diameter not exceeding 3Å. It is primarily used for adsorbing water. During the water adsorption process, 3A molecular sieve can exclude other hydrocarbon molecules. It is widely used for the deep drying of petroleum cracked gases, such as ethylene, propylene, butadiene, acetylene, and natural gas. It is also suitable for drying polar liquids (e.g., ethanol), liquefied petroleum gas (LPG), solvents, etc. Furthermore, it is extensively used as a desiccant for air in insulated glass units. Our company's 3A high-strength molecular sieve has been widely adopted by numerous manufacturers both domestically and internationally.

4A High-Strength Molecular Sieve has a pore size of 4Å and can adsorb molecules with a critical diameter not exceeding 4Å. It can adsorb water, hydrogen sulfide, carbon dioxide, sulfur dioxide, methanol, ethanol, ethylene, propylene, ethane, etc. It is suitable for static dehydration in sealed gas or liquid systems, acting as a static desiccant in household refrigeration systems, pharmaceutical packaging, electronic components, and perishable chemicals, or as a dehydrating agent in coating and plastic systems. Our company's 4A high-strength molecular sieve has been widely adopted by numerous manufacturers both domestically and internationally.

5A High-Strength Molecular Sieve has a pore size of 5Å and can adsorb molecules with a critical diameter not exceeding 5Å. It can adsorb all molecules that are adsorbable by 3A and 4A molecular sieves. Currently, its main applications include the separation of normal and iso-paraffins, adsorbing water, carbon dioxide, and acetylene from air in air separation for oxygen production, drying and desulfurization of gases and liquids, and in oxygen-enrichment devices for nitrogen-oxygen separation. Our company's 5A high-strength molecular sieve has been widely adopted by numerous manufacturers both domestically and internationally.

Application Fields

3A High-Strength Molecular Sieve: Petrochemical Industry; Insulated Glass; Food Industry; Medical Industry; Other New Technology Fields.

4A High-Strength Molecular Sieve: Petrochemical Industry; Household Refrigeration Systems; Coating and Plastic Systems; Electronic Components; Pharmaceutical Packaging; Saturated Hydrocarbon Materials.

5A High-Strength Molecular Sieve: Petrochemical Industry; Metallurgical Industry; Semiconductor & Electronics Industry; Gas Chromatography; Catalyst Research; Other New Technology Fields.

The key technical indexes of 3A High-intensity molecular sieve

NName of Indexame of Index | Spherical particle size(mm) | ||

∮2-3 | ∮3-5 | ||

Static water adsorption capacity wt% ≥ | 20.0 | 20.0 | |

Bulk density Kg/L ≥ | 0.70 | 0.68 | |

Rate of wear % ≤ | 0.3 | 0.3 | |

Grain size pass rate % ≥ | 96 | 96 | |

Compressive strength, N per piece≥ | 60 | 80 | |

Moisture content of packaging materials % ≤ | 1.5 | 1.5 | |

3A | Static ethylene adsorption mg/g ≤ | 3.0 | 3.0 |

4A | --- | --- | --- |

5A | Static n-hexane adsorption | 13.0 | 13.0 |

3A | adsorbs molecules | Molecules with an effective diameter less than 3A | |

4A | adsorbs molecules | Molecules with an effective diameter less than 4A include C2H5OH, H2S, CO2, C2H4, SO2, C2H6 | |

5A | adsorbs molecules | Molecules with an effective diameter less than 5A Including C3H8, n-C4H10 to C22H46, n-C4H9OH | |

* The number of grams of water adsorbed by 100 grams of activated molecular sieve at normal pressure and 35℃ temperature

These are the technical indicators of the commonly used 3A high-strength molecular sieve. Our company can adjust the parameter indicators according to the actual situation of the application manufacturers.

Recovery: 3A, 4A, 5A high-strength molecular sieves can be recovered and reused. The recovery gas is generally hot and dry gas. The degree of recovery depends on the recovery time and the temperature and humidity of the recovery gas.

Packaging and Storage Method

The products are packed in cardboard boxes or paperboard barrels (lined with woven bags and plastic bags), and stored in a dry place.