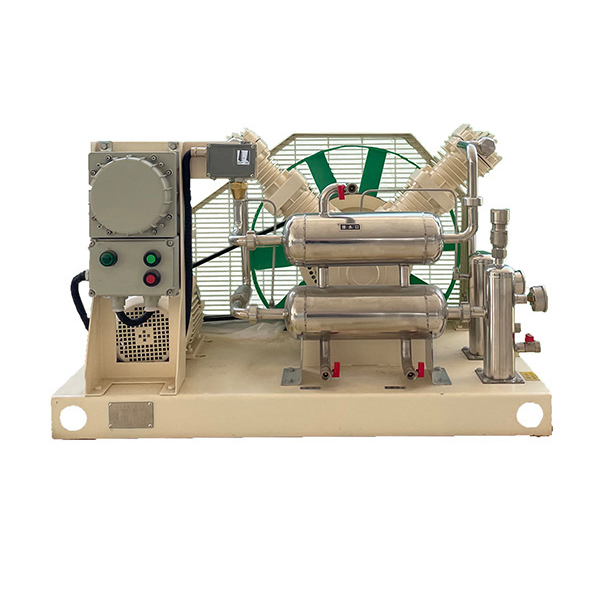

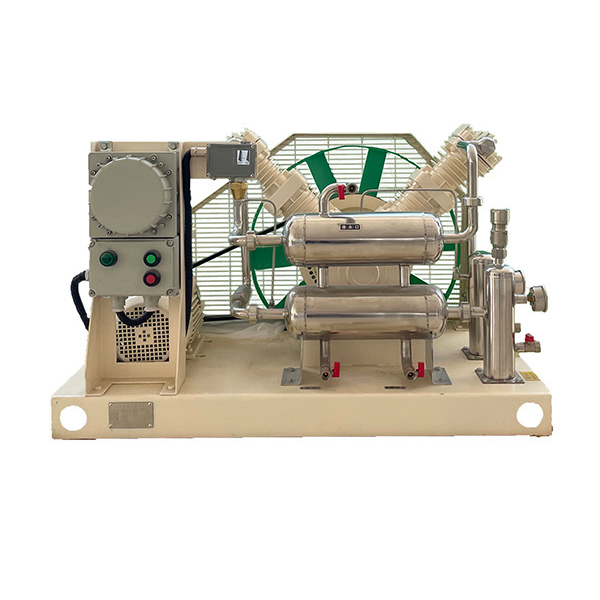

High Pressure Hydrogen Booster Compressors | Leading Manufacturer of Hydrogen Gas Compression Systems

Product Details

● Full oil-free design, guide ring, piston ring, piston rod packing are all made of self-lubricating materials, 100% oil-free lubrication. Bearing parts are lubricated with high temperature resistant grease, not in contact with the compression medium, avoiding the pollution of the gas in the compression process and ensuring the purity of the gas. According to the actual gas situation, the compressor is divided into single-stage or multi-stage compression; structural form is divided into single-cylinder, double-cylinder, triple-cylinder, quadruple-cylinder and combined multi-cylinder structure; cooling mode is divided into air-cooled and water-cooled. ● Microcomputer controller control, with high compressor discharge temperature, low inlet pressure, exhaust pressure, such as alarm stop function, high level of automation, stable and reliable operation of the compressor. According to customer requirements can be configured data remote display and remote control. ● This series of compressor is suitable for hydrogen production system such as water electrolysis hydrogen production, laboratory hydrogenation reaction, hydrogen cycle test, tar hydrogenation, catalytic cracking and other chemical processes. ● Suction pressure: 0~ 0.6Mpa (G), discharge pressure: ≤5 Mpa (G). |

|

What is a Hydrogen Compressor?

A hydrogen compressor can be considered like a high-power high-precision pump for hydrogen gas. It compresses hydrogen into a space vastly smaller, raising its pressure by several orders of magnitude. High pressure hydrogen is needed for many industrial processes, energy applications or to be made into liquid hydrogen for storing and transporting.

About us

Jiangsu Hongbo Group Co., Ltd. was founded in 2006 with a registered capital of RMB 55.6 million. It is a high-tech enterprise.The Suzhou office includes the Sales Department, After-sales Service Department and the 800 m² overhaul workshop along with the 400 m² product exhibition room.Hongbo is R&D, design and manufacture integration,occupying an area of 15000 square meters with the workshop area of 8000 square meters.

Hongbo employs over150 people, including 16 engineers and 18 after-sales service staff. Among them are 3 senior engineers, 2 with master series, 11 with bachelor series and 30 with associate series — which Ub potential is a strong foundation for the standardized mass production of Hongbo products. has been widely used in major industries such as chemical fiber, pharmaceutical, environment protection, electronics, lithium battery, new energy, food keep, steel, powder metallurgy, heat treatment, petrochemical, offshore oil, warehouse and wharf, and military aerospace.

FAQ

1. What's payment term?

T/T, L/C, Paypal and etc. Also we could accept USD, RMB, Euro and other currency (Pls contact our sales for more information

2.How about your customer service?

24 hours on-line service available

3. What pressure range can hydrogen booster compressors achieve?

High pressure hydrogen booster compressors typically support discharge pressures from 200 bar up to 900 bar, depending on the compressor design and application requirements.

4. Are hydrogen booster compressors oil-free?

Yes. In order to avoid contamination, risk of explosion and loss of hydrogen purity, the majority of hydrogen booster compressors are fully oil-free.

5. What maintenance is required for hydrogen booster compressors?

General maintenance consist of checks of the seals or diaphragms, cooling systems, valves, sensors, and safety systems. There is no need to change the oil with oil-free models.

6. Are hydrogen booster compressors energy-efficient?

Yes. With today’s systems, they employ stage compressions, efficient drives and intelligent control logic to reduce the energy consumption at the elevated pressure.