Hydrogen Gas Plant Methanol cracking for hydrogen production generator

Product Introduction

CJDL-I serise machine is a thermal treatment protective atmosphere generator jointly developed by our company and the Applied Chemistry Research Institute of North University under the direct jurisdiction of the Ministry of National Defense.

How it works of the CJDL-I serise machine :First, vaporize the incoming methanol to a specific temperature range. The methanol vapor then comes into full contact with the catalyst in a low-temperature environment (260°C), where it decomposes to produce a reductive mixed gas primarily consisting of hydrogen and carbon monoxide. This mixed gas is then cooled using specialized condensation equipment based on its different components and dew point temperatures before entering the thermal treatment device.

Reducing gas mixture produced enters the furnace chamber and reacts chemically with the small amount of oxygen brought in by the workpieces and the oxidized surface of the workpieces at high temperatures. The reaction products are H2O and CO2. This oxidative atmosphere is displaced from the furnace chamber as more cracking gas mixture enters, ultimately achieving chemical equilibrium within the furnace atmosphere, thus realizing the purpose of atmosphere protection.

CJDL-I serise Methanol low-temperature cracking machine

● CJDL-I serise machine is a thermal treatment protective atmosphere generator jointly developed by our company and the Applied Chemistry Research Institute of North University under the direct jurisdiction of the Ministry of National Defense. How it works of the CJDL-I serise machine :First, vaporize the incoming methanol to a specific temperature range. ● The methanol vapor then comes into full contact with the catalyst in a low-temperature environment (260°C), where it decomposes to produce a reductive mixed gas primarily consisting of hydrogen and carbon monoxide. This mixed gas is then cooled using specialized condensation equipment based on its different components and dew point temperatures before entering the thermal treatment device. |  |

| Methanol cracking for hydrogen production generator technical specifications | |||

| molecular formula | CH3OH | Cracking energy consumption | 0.8KW/m³ |

| molecular weight | 32 | Relative density of pyrolysis gas | 0.385 |

| specific gravity | 0.792 | Methanol vapor relative density | 1.11 |

| boiling point | 64.7℃ | Cracking gas relative volume ratio | 0.000712963 |

| specific heat | 18.4KCal/℃.mol | The main components of pyrolysis gas | H2、CO |

| Methanol autoignition temperature | 470℃ | Pyrolysis gas autoignition point | 740℃ |

| Implement standards | GB T338-2011 | Design pressure | 0.4MPa |

| Pyrolysis temperature | 220-350℃ | Safety valve opening pressure | ≤0.3MPa |

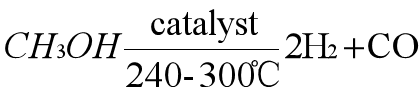

CH3OH Cracking reaction equation

| For example, the low-temperature cracking reaction equation of 99.9% industrial methanol is: |  |

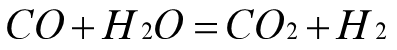

Water gas equilibrium reaction equation

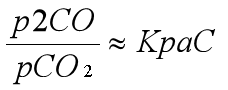

Cracking gas composition

At 900°C, the composition of the cracking gas and furnace gas when using 99.9% methanol as raw material is as follows(Tube furnace):

| Category | Gas composition (%) | |||

| H2 | CO | CO2 | CH4 | |

| cracked gas | 66 | 33 | 0.5 | 0.2 |

| furnace gas | 66.5 | 32 | 0.2 | 0.2 |

CJDL-I serise Methanol low-temperature cracking machine

1. The process of atmosphere protection in metal heat treatment involves continuous cycles of oxidation and reduction reactions. The ultimate goal of atmosphere protection is to maintain a balance between oxidation and reduction reactions within the furnace. Typically, people adjust the protective atmosphere appropriately to meet the heat treatment requirements of different metal materials. However, the protective atmosphere for heat treatment should generally satisfy:

It has already successfully replaced ammonia decomposition equipment in multiple industry sectors.

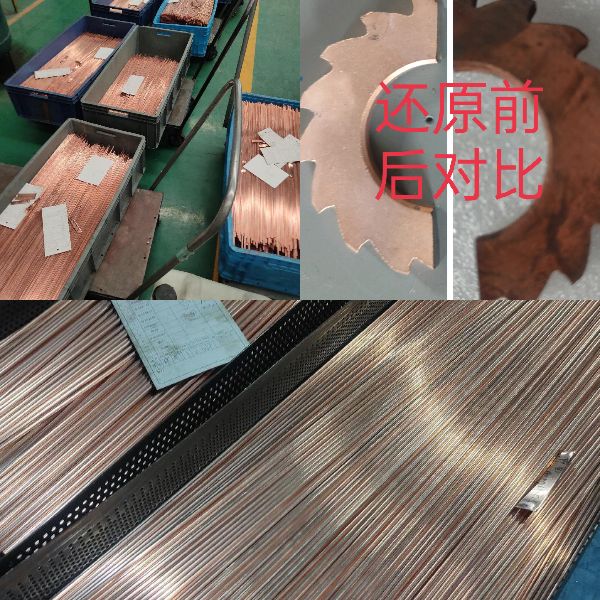

2.Crackers are currently widely used in various metal heat treatment fields: bearing steel annealing/quenching protection, wire annealing, carburizing, and quenching protection in the fastener industry, mold steel quenching protection, tool steel annealing/quenching protection, copper annealing and brazing protection, powder metallurgy, and heat treatment protection for various automotive parts.

Energy Saving VSD Air Compressor for Industrial Use.

FAQ

1.Why customer choose us?

Jiangsu Hongbo Gas Equipment Technology Group Co, Ltd. is a professional manufacturer for green gas plant, such as PSA nitrogen generator, VPSA Oxygen generator, Hydrogen generator, gas purification equipment, air compressor etc.. We have more than 20 years experience in producing and exporting those machines and spare parts.

2.Are you a manufacturer or trading company?

Our headquarters is located in Suzhou, China, factory is located in Dongtai, Yancheng City, Jiangsu, China. We have research and develop center, advanced processing equipment, professional technicians, rich experience workers and after-sales team to offer good quality products and good service to our customers. We also can provide you the OEM&ODM service.

3.What's your delivery time?

Generally 10-45 days, if urgently order, pls contact our sales in advance.

4.How long is your PSA nitrogen&VPSA Oxygen generator and air compressor warranty?

One year for the whole machine when the machines leave our factory.

5.How long could your PSA nitrogen, VPSA Oxygen generator air compressor be used?

Generally, more than 10 years.

6.What's payment term?

T/T, L/C, Paypal and etc. Also we could accept USD, RMB, Euro and other currency (Pls contact our sales for more information

7.How about your customer service?

24 hours on-line service available

8.How about your after-sales service?

1. Provide customers with installation and commissioning online instructions.

2. Well-trained engineers available to overseas service

3. World wide agents and after service available