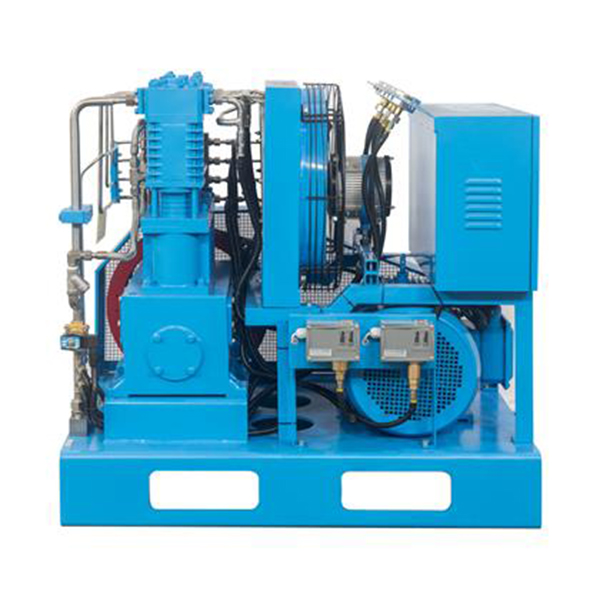

Manufacturer of Oil-Free Air Compressors for Oxygen Plants and Industrial Applications

Product Details

1.Totally oil free ,absolute no oil inside, very safety.

2.4 cylinder in line design ,all cylinder vertical cylinder ,both piston left and right side same working condition,and same worn condition ,last longer maintenance time.

3.Vertical cylinder and piston working condition,There is no lateral force, only acting in the vertical direction,Energy saving ,less electrical consumption for same gas work.

4.4 pressure stage design ,each stage has safety valve each stage pressure ratio 2-4 ,get balanced pressure for fronter and later cylinder, the overall cylinder has good heat dissipation and balanced stress, and all this make the compressor working heavy duty in long time.

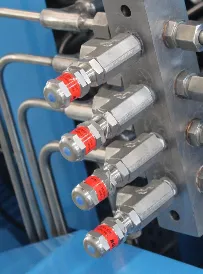

5.Patent piston and piston ring design ,including guide ring and seal ring,Self lubricating material ,no oil inside ,special Material formula.

Decrease gas leakage and make compressor working in high pressure and high temperature condtion.

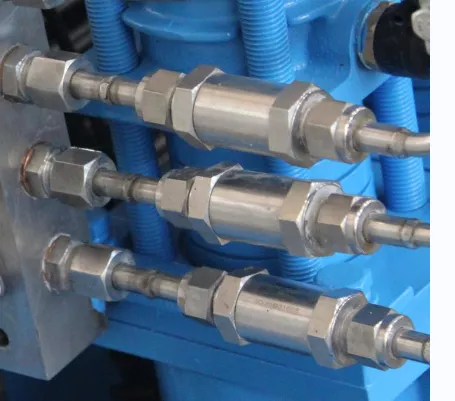

6.Suction terminal Y type filter ,Filter molecular sieve powder in oxygen generator.

1-2-3stasge cylinder has one stainless filter ,change filter element in time and make the compressor working longer and high efficiency.

When we engineer and manufacture systems to handle reactive gases such as oxygen, we integrate safety at every level:

1. Spotlessly clean All oxygen-exposed parts are covered with a specialized cleaning and degreasing solution to remove any trace of hydrocarbon contamination prior to assembly.

2. Rigor Maintenance: We educate our clients that any maintenance needs to be done with impeccably clean and oil free hands, tools, and work areas or you just introduce risk while servicing.

3. Smart Controls: Our high-accuracy controls used on our compressors allow you to track pressure, temperature, cooling flow. You need to cool it properly because too much heat in an oxygen atmosphere is hazardous. If by chance-there are alerts and automatic stop measures built right in to the design.

4. High O-Ring Efficiency: Advanced sealing technology is used to prevent external lubricants from the motor and/or gears from penetrating into the oxygen compression chamber.

About us

Jiangsu Hongbo Group Co., Ltd. established in 2006, is 15,000 m² in area, with 8,000 m² workshop. Hongbo now has more than 150 staffs with 16 engineers and 18 after-sales service staffs. Among them are 3 senior engineers, 2 of them holds master’s degree, 11 of them holds bachelor’s degree, 30 of them holds associate degree and so on and so forth, this form a strong base for HK standardized mass production.

has been widely used in the field of chemical fiber, pharmaceutical, environmental protection, electronic, lithium battery, new energy, food storage, steel, powder metallurgy, heat treatment, petrochemical, oil drilling, logistics, as well as in the field of national defense and aerospace.

FAQ

1. What's payment term?

T/T, L/C, Paypal and etc. Also we could accept USD, RMB, Euro and other currency (Pls contact our sales for more information

2.How about your customer service?

24 hours on-line service available

3. Are oil-free air compressors safe for use in a high oxygen environment?

Yes. Oil-free compressors have been specifically designed for safe use in oxygen service, with greatly reduced risk of ignition and the ability to meet the stringent oxygen system safety requirements.

4. What air quality standards are applicable to oxygen plant?

Oil-free air compressors for oxygen plant and its compressed air supply normally comply with the ISO 8573-1 CLASS 0, which describes the oil content in an oil free compressed air supply.

5. Can I use oil-free air compressors long time in oxygen plant?

Yes. Oil-free compressors are designed for continuous operation with constant flow and pressure, and oxygen plants are generally 24-hour operations.

6. Are air dryers and filters still required in oxygen plant?

Yes. Air dryers, and high efficiency filters are needed to take out moisture and particulates before the air goes into the oxygen separation even with oil free compression.