Oil-Free Industrial Oxygen Compressors & High-Pressure Tank/Concentrator Compressors

Product Details

An oxygen booster (or oxygen compressor) is not a device that you can use for any kind of scenario, it's rather a very restricted use tool. It is, in fact, a very specialized tool that's only used in the few instances where the purity, pressure, and safety of oxygen are of utmost importance. These are the major areas where an oxygen booster is indispensable:

1. Healthcare & Life Sciences: There is no doubt that this is the most sensitive application by far. Hospitals and medical facilities use oxygen boosters to refill or maintain pressure in the oxygen cylinders and central pipeline systems through which oxygen is supplied for patient therapy, ICU ventilators, and operating rooms. In this scenario, 99.5%+ oxygen purity and absolutely, certified oil-free operation is a must to safeguard the patient’s health. If what you do involves breathing and healing, you simply cannot compromise!

2. Manufacturing & Metal Fabrication: For oxy-fuel cutting and welding, the use of high-purity, high-pressure oxygen allows a clean, hot flame for cutting through thick steel or joining metals. A trustworthy oxygen booster makes sure that the gas delivery is always consistent, which therefore results in better cuts and welds as well as less downtime of production on the shop floor.

3. Water Treatment & Environmental: Nowadays a lot of water treatment plants employ ozone (generated from oxygen) to disinfect water. An oxygen booster provides high-pressure oxygen to ozone generators thus the whole process becomes more efficient and effective. Picking the right oxygen booster here means that you are embracing green technology by being backed up with the dependable performance throughout.

4. Aerospace & High-Tech Research: Whether it is about providing breathable oxygen for the crew of an airplane or facilitating combustion in highly specialized laboratory tests, these fields demand technical equipment that can offer extreme reliability, very fine pressure control, and components made of high-quality materials compatible with high-purity gases.

5. Energy & Chemical Processes: Some operations in gasification, chemical synthesis, or enhanced oil recovery involve oxygen as a reactant. An oxygen booster will help ensure that it's delivered at a suitable pressure for attaining optimum reaction rates and process control.

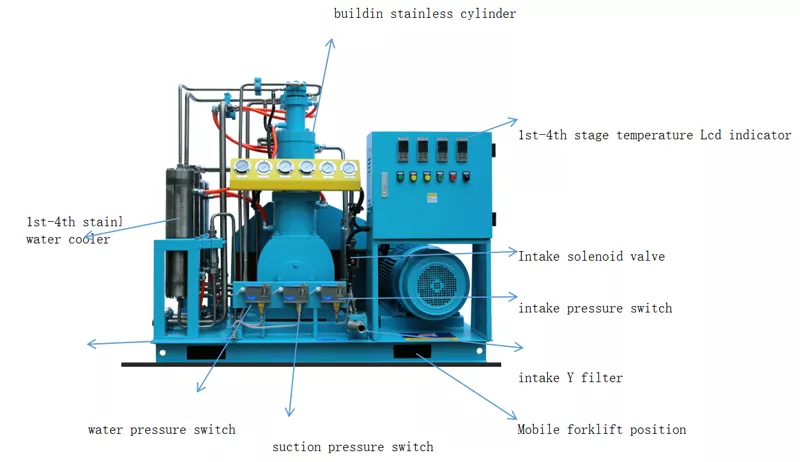

Our reciprocating industrial oxygen compressor have the following features.

1.Completely 100% oil free, no oil required (depending on the specific model).

2.Cylinder Cast stainless steel.

3.Oxygen for VPSA PSA and LOX gas source.

4.NO pollution, keep the same purity into the gas.

5.High reliability and high quality, comparable to the American RIX brand.

6.Low maintenance cost and simple operation.

7.4000 hours piston ring working life under low pressure conditions, 1500-200O hours working life under high pressure conditions.

8.TOP brand motor, can be specially pointed out, just like the SIMENSE brand.

9.Supply customers in the Japanese market, in line with Japan's demanding quality requirements.

10.CE approved to meet the requirements of the EU market.

11.According to the customer's specific working conditions, the compressor is designed for single machine compression, two-stage compression, three-stage compression and four-stage compression.

12.Low speed, long life, average speed 260-350RPM.

13.Low noise, average noise below 75dB, can work quietly in the medical field.

14.continuous continuous heavy-duty operation, can run stably for 24 hours without stopping.

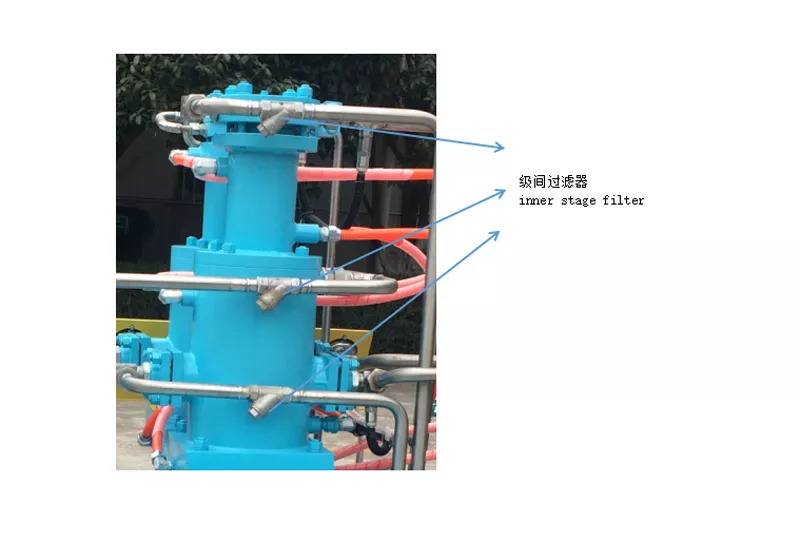

15.Each stage has an interstage safety valve. If the stage is overpressured, the safety valve will take off and release the overpressure gas to ensure the stable operation of the compressor.

16.Each level has a temperature controller. If the temperature between the stages exceeds the standard, the temperature display will sound and light alarm.

All standard industrial reciprocating oxygen compressor supplier are CE marked to meet the requirements of the EU market. We can also provide customized oxygen compressors according to customer conditions.

|  |

|  |

| |

Our advantages

This is how we put that principle into practice:

1. A Total No-Oil Rule: This is THE rule. The chamber of compression should be totally void of any hydrocarbon-base oils and greases. We accomplish this through unique solutions such as water-lubricated cylinders or sophisticated dry-running (oil-free) technologies. Prior to assembly, each part is thoroughly washed with certified solvents to guarantee no contamination.

2. Doing Officer the Choice of the Right Materials: IP is moist and humid oxygen under pressure and oxygen can be corrosive. Thus, we use materials that are compatible, robust, safe. Phosphor bronze, for example, may be used for cylinders; specialized aluminum alloys for pistons; and copper or stainless steel for intercoolers—all selected for their corrosion resistance and heat-safe properties.

3. Gentle and Controlled Compression: We design for the middle road. To prevent heat and friction generation, piston speeds and gas flow velocities are lower than those of air compressors. We impose rigid controls on the compression ratio at each stage, as well as on the final discharge temperature, to ensure that all operations are conducted well within safe operational limits.

The Dependable Workhorse: Piston Compressor Technology

At Jiangsu Hongbo, we are professional in pistontype oxygen compressor.

For numerous applications the practical features of the piston compressor cements it as an excellent option:

Flexibility and Power: It delivers an extensive range of pressure and flow, and can be customized to meet your specific application requirements.

Tested Efficiency and Cost-effectiveness:this design is thermally efficient, leading to lower operating costs. The technology is established, so parts are available, service is established and and initial cost is frequently favorable.

Built to last and with a straightforward design for easy, simple to clean servicing that will not let you down.

That same reliable piston technology is also the basis for our other gas compressors (nitrogen and hydrogen units), which says a lot for its trusted design. Although each technology has its idiosyncrasies, the well-proven performance, safety and flexibility of a well-designed piston compressor still establishes it as the safe choice for critical oxygen applications.

About us

Jiangsu Hongbo Group Co., Ltd. was founded in 2006 with an 800 m² maintenance workshop and a 400 m² product exhibition hall.

Dongtai Hongbo is a high-tech enterprise integrating r&d, design and production, Dongtai Hongbo covers an area of 15000 m², with 8000 m² workshop.

The company values technology innovation and intellectual property protection greatly. So far it has been granted 1 invention patent, 21 utility model patents and 3 software copyright certificates, etc. has been in great demand in many major industries such as chemical fiber, pharmaceutical, environmental protection, electronic, lithium battery, new energy, food preservatives, steel, powder metallurgy, heat treatment , petrochemical, oil drilling, storage and transportation, and national-defense aeri-space.

FAQ

1.What's payment term?

T/T, L/C, Paypal and etc. Also we could accept USD, RMB, Euro and other currency (Pls contact our sales for more information

2.How about your after-sales service?

1. Provide customers with installation and commissioning online instructions. 2. Well-trained engineers available to overseas service 3. World wide agents and after service available

3. What are the pressure ranges for filling a high pressure cylinder?

Oil-free oxygen compressors may cover a wide range of pressures from 30 bar to 300 bar or ~4350 psi based on the system design and cylinder specifications.

4. Is there any need for extra filtering when compressing oxygen?

Yes“ High efficiency particle filters and oxygen compatible dryers are recommended for oil free compression as well to maintain system integrity and safety.

5. In what way does oil-free compression increase equipment life?

By avoiding oil contamination, oil-free compressors also prevent the fouling of valves and subsequent corrosion in the system, which means that tanks, pipes, and concentrators will their service life extended.

6. Do oil free oxygen compressors use less energy?

Yes. High efficiency motors, optimized compression stages and variable speed control (optional) have been utilized to reduce the energy consumption in the latest version.