Box-type Nitrogen Generator

Pressure swing adsorption (PSA) nitrogen generator is an automatic equipment which uses carbon molecular sieve as adsorbent, and uses the principle of pressure adsorption and pressure reduction desorption to absorb oxygen from air, thus separating nitrogen.

Product Introduction

|  |

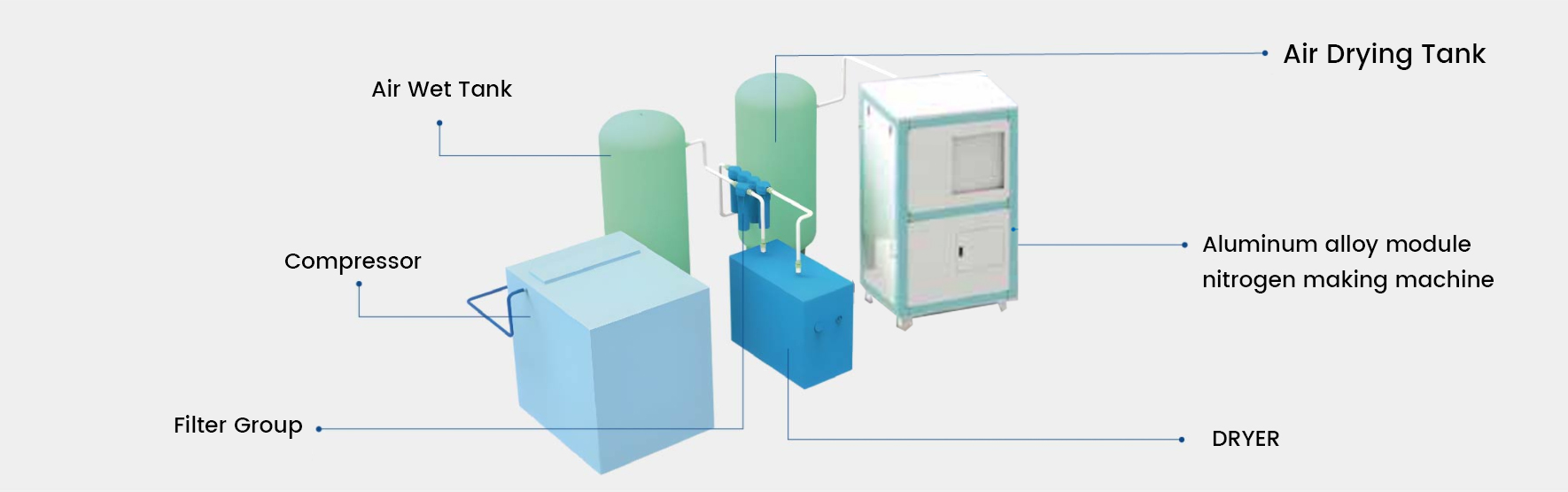

Flow Chart Of Nitrogen Machine

Product Parameters

| HBFD(Box Nitrogen generator) | ||||||

| Model | Nitrogen purity | Nitrogen production | (Nm³/min) Effective air consumption | (DNmm) Inlet pipe size | (DNmm) Outlet pipe diameter | L*W*H(mm) Host |

| HBFD-1 | 29 | 5.5 | 0.19 | DN15 | DN15 | 800*650*1240 |

| 295 | 4.5 | 0.18 | ||||

| 39 | 3 | 0.15 | ||||

| 49 | 1.5 | 0.11 | ||||

| 59 | 1 | 0.09 | ||||

| HBFD-2 | 29 | 8.5 | 0.30 | DN15 | DN15 | 800*650*1720 |

| 295 | 6 | 0.24 | ||||

| 39 | 4.5 | 0.23 | ||||

| 49 | 3 | 0.22 | ||||

| 59 | 1.5 | 0.14 | ||||

| HBFD-3 | 29 | 20 | 0.70 | DN15 | DN15 | 950*950*1500 |

| 295 | 16 | 0.65 | ||||

| 39 | 11.5 | 0.58 | ||||

| 49 | 6.5 | 0.47 | ||||

| 59 | 4.5 | 0.42 | ||||

| HBFD-4 | 29 | 30 | 1.05 | DN20 | DN15 | 1050*900*1870 |

| 295 | 25 | 1.02 | ||||

| 39 | 18 | 0.91 | ||||

| 49 | 10 | 0.72 | ||||

| 59 | 7 | 0.65 | ||||

| HBFD-5 | 29 | 55 | 1.93 | DN25 | DN15 | 1150*1130*2010 |

| 295 | 45 | 1.83 | ||||

| 39 | 33 | 1.66 | ||||

| 49 | 20 | 1.44 | ||||

| 59 | 13 | 1.21 | ||||

| HBFD-6 | 29 | 30 | 1.05 | DN20 | DN15 | 1360*1100*1870 |

| 295 | 25 | 1.02 | ||||

| 39 | 18 | 0.91 | ||||

| 49 | 10 | 0.72 | ||||

| 59 | 7 | 0.65 | ||||

| HBFD-7 | 29 | 75 | 2.63 | DN25 | DN20 | 1250*1250*2010 |

| 295 | 60 | 2.44 | ||||

| 39 | 45 | 2.27 | ||||

| 49 | 28 | 2.02 | ||||

| 59 | 20 | 1.87 | ||||

| HBFD-8 | 39 | 65 | 3.27 | DN40 | DN25 | 1500*1350*2200 |

| 49 | 40 | 2.88 | ||||

| 59 | 26 | 2.43 | ||||

| HBFD-9 | 39 | 80 | 4.03 | DN40 | DN25 | 1500*1350*2200 |

| 49 | 48 | 3.46 | ||||

| 59 | 33 | 3.08 | ||||

| HBFD-10 | 39 | 90 | 4.53 | DN40 | DN40 | 1550*1450*2200 |

| 49 | 55 | 3.96 | ||||

| 59 | 38 | 3.55 | ||||

| HBFD-11 | 39 | 140 | 7.7 | DN40 | DN40 | 1750*1850*2350 |

| 49 | 80 | 5.2 | ||||

| 59 | 50 | 4.8 | ||||

| HBFD-12 | 39 | 170 | 9.4 | DN50 | DN40 | 1850*1900*2450 |

| 49 | 100 | 6.5 | ||||

| 59 | 60 | 5.8 | ||||

I. Core Technology: Box-integrated Pressure Swing Adsorption (PSA) Precision Separation System

The Pressure Swing Adsorption (PSA) nitrogen generator is an automated device that uses carbon molecular sieve as adsorbent. It adsorbs oxygen from the air based on the principle of pressurization adsorption and depressurization desorption to separate nitrogen. The core technology of this box-type nitrogen generator is based on the Pressure Swing Adsorption (PSA) process, with all functional modules highly integrated into a closed box. When compressed air is connected to the box interface through external pipelines, it first enters the built-in air pretreatment system (including precision filters and refrigerated dryers) to quickly remove dust, oil and moisture from the air, ensuring the air entering the adsorption tower meets the "oil-free, water-free and dust-free" cleanliness standard. Subsequently, the clean air enters the adsorption tower inside the box. Under the working pressure of 0.7-0.8MPa, the molecular sieve in the tower preferentially adsorbs impurities such as oxygen and carbon dioxide, while nitrogen passes through the molecular sieve to become qualified nitrogen, which is delivered to the customer's usage point through pipelines.

The device is equipped with two adsorption towers inside the box, which are automatically controlled by the PLC system to alternately perform the "adsorption-desorption" cycle. When the molecular sieve in one adsorption tower reaches saturation, the system switches to the other tower to continue adsorption, and at the same time, depressurizes and desorbs the saturated tower to desorb the adsorbed impurities and restore the adsorption capacity of the molecular sieve. This cycle mode realizes the continuous production of nitrogen. The closed structure of the box not only reduces the interference of external dust and water vapor on internal modules, but also makes the equipment appearance neat and uniform, perfectly complying with the 5S management standards of the workshop.

II. Raw Material Advantage: "Zero Raw Material Restriction" Gas Production Mode Under Box-type Design

This box-type nitrogen generator uses natural air as the only raw material. It can start production only by connecting the factory's existing compressed air system to the box interface through pipelines and supplying industrial power to the box. Its raw material advantages are completely realized by the box-type integrated design:

• No procurement cost: No need to purchase additional chemical raw materials, completely avoiding the procurement expenditure of liquid nitrogen and bottled nitrogen. The on-site gas production mode of the box-type directly converts "air" into usable gas source.

• No storage risk: The box-type structure does not require dangerous storage containers such as low-temperature liquid nitrogen tanks and high-pressure gas cylinders, avoiding potential safety hazards such as low-temperature frostbite and gas cylinder explosion, making the gas use in the workshop safer.

• No supply restriction: Air is an unlimited raw material, and production is not affected by logistics or supplier capacity. Even in extreme weather or supply chain disruption, the box-type equipment can continuously supply gas to the production line, perfectly adapting to the industrial scenario of continuous production.

III. Flexible Purity: One-click Adjustment via Box Touch Screen, Covering Full Industry Needs

The box-type nitrogen generator supports flexible adjustment of nitrogen purity between 90% and 99.999% ("five 9s"). The purity adjustment can be directly completed through the high-definition touch screen installed outside the box, without disassembling the box or adjusting internal components, which is convenient and efficient. Meanwhile, different purities accurately match the differentiated scenarios of various industries:

• 90%-95% purity: Suitable for basic scenarios such as simple industrial purging, protection, and ordinary packaging filling, meeting the demand for low-cost inert protection.

• 99.5%-99.9% purity: Adaptable to scenarios such as electronic component packaging, plastic product injection molding protection, and food preservation, avoiding oxidation and deterioration of products caused by contact with oxygen.

• 99.99%-99.999% purity: Targeting high-precision industries—such as inert protection for semiconductor wafer lithography, isolation of production environment for pharmaceutical sterile preparations, and storage protection for high-end chemical raw materials. Nitrogen of this purity can avoid the impact of trace impurities on product quality, serving as the core guarantee gas source for high-end manufacturing.

IV. Economical and Practical: "Small Space, Low Cost" Advantages Brought by Box Integration

The box-type nitrogen generator gives full play to the characteristics of box-type integration in design, with comprehensive practical value of "cost reduction and efficiency improvement":

• Simplified process and easy installation: The box-type equipment adopts a fully integrated design, with all functional modules pre-installed in the box. On-site installation is extremely simple—only need to connect the compressed air pipeline to the corresponding interface of the box and switch on the 380V industrial power supply to complete the basic deployment. No complex infrastructure projects are required, and it can be installed, commissioned and put into use within 1-2 days after arrival.

• Compact footprint and flexible layout: The box-type structure adopts a vertical layout. The small box model (gas production capacity 5Nm³/h) covers only 2-3 square meters, and the large box model (gas production capacity 50Nm³/h) only needs 5-6 square meters of space, which can be flexibly placed in the corner of the workshop. Some lightweight box models are also equipped with mobile casters, which can be directly moved when the workshop adjusts the production layout, greatly improving the flexibility of space utilization.

• Low energy consumption and long-term cost reduction: The unit nitrogen energy consumption of the box-type equipment is only 0.3-0.8kW·h/Nm³ (slightly different according to gas production capacity and purity), which is much lower than the comprehensive energy consumption of traditional nitrogen production methods. Combined with the on-site gas production mode, there is no need to bear additional costs for liquid nitrogen transportation and bottled gas handling. In the long run, the nitrogen production cost is 30%-50% lower than that of purchasing liquid nitrogen, bringing continuous cost savings to enterprises.

V. Core Consumable Guarantee: Box Protection + Blizzard Packing, Extending Molecular Sieve Lifespan

Molecular sieve is the core consumable of the box-type PSA nitrogen generator, and its state directly determines the gas production capacity and purity stability of the equipment. The traditional manual packing method is prone to uneven density and high porosity of molecular sieve. Under the impact of high-pressure air flow, the molecular sieve is easy to loosen and pulverize, leading to rapid decline in adsorption efficiency, and the equipment needs frequent replacement of consumables.

The adsorption tower of this box-type nitrogen generator is built into the box, and its molecular sieve adopts the "Blizzard Packing Method": through special high-pressure packing equipment, the molecular sieve is filled into the adsorption tower in a uniform and high-density state, controlling the porosity between molecular sieve particles at an extremely low level with strong structural stability. This packing method can resist the impact of long-term high-pressure air flow and avoid molecular sieve pulverization. At the same time, the closed protective structure of the box reduces the impact of the external environment (such as humidity and dust) on the adsorption tower, extending the service life of the molecular sieve to 3-5 years (only 1-2 years for traditional packing), reducing the frequency of consumable replacement and equipment downtime, and ensuring production continuity.

VI. Wide Adaptability: Box-type Structure Adapts to Core Scenarios of Multiple Industries

With the convenience of the box-type structure, flexible purity adjustment, stable gas production capacity and economical operating cost, the box-type nitrogen generator has been widely used in various industrial fields:

• Electronic manufacturing industry: SMT industry, inert protective gas for semiconductor wafer lithography, anti-oxidation protective gas for electronic component welding (the box-type equipment can be directly placed next to the workshop production line, reducing pipeline loss).

• Food industry: Inflatable packaging of puffed food (anti-oxidation and moisture-proof), modified atmosphere preservation of fruits and vegetables (adjusting nitrogen-oxygen ratio).

• Pharmaceutical industry: Inert atmosphere protection in pharmaceutical production workshops, filling protective gas for sterile preparations (the dust-proof characteristics of the box-type adapt to the clean workshop environment).

FAQ

1.Why customer choose us?

Jiangsu Hongbo Gas Equipment Technology Group Co, Ltd. is a professional manufacturer for green gas plant, such as PSA nitrogen generator, VPSA Oxygen generator, Hydrogen generator, gas purification equipment, air compressor etc.. We have more than 20 years experience in producing and exporting those machines and spare parts.

2.Are you a manufacturer or trading company?

Our headquarters is located in Suzhou, China, factory is located in Dongtai, Yancheng City, Jiangsu, China. We have research and develop center, advanced processing equipment, professional technicians, rich experience workers and after-sales team to offer good quality products and good service to our customers. We also can provide you the OEM&ODM service.

3.What's your delivery time?

Generally 10-45 days, if urgently order, pls contact our sales in advance.

4.How long is your PSA nitrogen&VPSA Oxygen generator and air compressor warranty?

One year for the whole machine when the machines leave our factory.

5.How long could your PSA nitrogen, VPSA Oxygen generator air compressor be used?

Generally, more than 10 years.

6.What's payment term?

T/T, L/C, Paypal and etc. Also we could accept USD, RMB, Euro and other currency (Pls contact our sales for more information

7.How about your customer service?

24 hours on-line service available

8.How about your after-sales service?

1. Provide customers with installation and commissioning online instructions.

2. Well-trained engineers available to overseas service

3. World wide agents and after service available