Containerized Membrane Nitrogen Generator

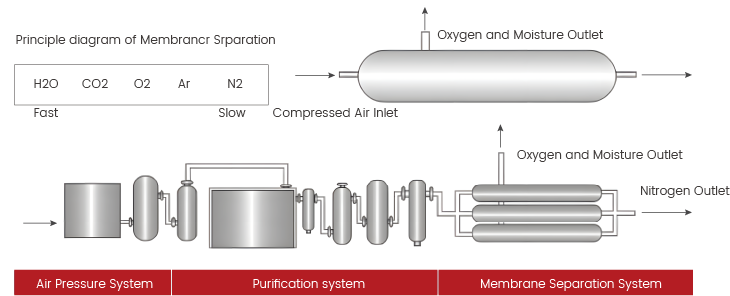

The main principle of membrane separation Nitrogen equipment is selective permeation. Each gas component in the air has its unique permeability and permeability in the polymer film, showing the ability to dissolve and diffuse in each component through the polymer film. According to this characteristic, the gas with faster permeability of polymer membrane can be separated from the slow gas such as nitrogen.

Product characteristics

Low-Cost Containerized Membrane Nitrogen Generator for Oil and Gas Industry: A Safe and Efficient On-Site Nitrogen Supply Solution.

|  |

Process flow diagram

I. Nitrogen Demand in the Oil and Gas Industry

In the entire process of oil and gas exploration, development, storage, transportation and operations, nitrogen is one of the core media to ensure safe and stable production:

• Safety inerting: A large number of flammable media such as crude oil and natural gas exist in oil and gas operation environments. Mixing with air is prone to forming explosive mixtures. As an inert gas, nitrogen can effectively reduce oxygen content and avoid explosion risks.

• Process support: Process links such as pipeline/tank cleaning and purging, drilling fluid aeration, and workover operation space protection all require dry and impurity-free gas as the medium.

II. Product Overview

This equipment is an integrated membrane nitrogen generation system customized for the oil and gas industry. With hollow fiber membrane separation technology as the core, it integrates functional modules such as compressed air pretreatment, membrane separation, nitrogen buffering, and intelligent control into a 20/40-foot standard container. It features "ready to transport, install and use": it can be directly transported to oil and gas operation sites (wellheads, tank farms, pipeline construction sections, etc.), and can be started and operated only by connecting pipelines and power supplies. It can stably supply nitrogen with a purity of 95%-99.9%, fully adapting to various safety and process requirements of the oil and gas industry.

III. Core Product Features

1. Membrane Separation System: A Simple, Low-Maintenance and Economical Nitrogen Generation Method

High-quality hollow fiber membrane modules are adopted to achieve air separation based on the "difference in membrane permeability rates of different gas molecules": after pretreatment, compressed air enters the membrane modules, small molecules such as oxygen and water vapor quickly permeate and are discharged, and nitrogen molecules are enriched into high-purity nitrogen.

Compared with traditional technologies, its advantages are:

• Extremely simple structure: No wearing parts such as switching valves and adsorption towers of PSA nitrogen generation, no chemical reaction links, and no mechanical wear during operation.

• Low energy consumption: Nitrogen generation only relies on the energy consumption of front-end air compression, and no additional energy consumption is required for subsequent separation. The long-term operation cost is 20%-30% lower than that of PSA nitrogen generation.

• Long service life: The designed service life of the membrane module is 5-8 years (under normal working conditions), no frequent replacement of core components is required, further reducing maintenance costs.

2. Few Wear Parts + Low Maintenance Workload: Adapting to the "Light Operation" Demand of Oil and Gas Sites

Aiming at the characteristics of limited personnel configuration and simple maintenance conditions at oil and gas sites, the equipment adopts a "few moving parts, high reliability" design:

• Maintenance-free core components: Membrane modules, nitrogen buffer tanks and other static components have no risk of operational wear.

• High durability of auxiliary components: Filters, regulating valves and other components adopt industrial-grade corrosion-resistant materials such as 304 stainless steel, with a failure rate of less than 0.5% per year.

• Extremely simple daily maintenance: Only the air filter element needs to be replaced every quarter (which can be completed in 5-10 minutes). Daily inspection of pressure and temperature parameters is only required, and no professional maintenance team is needed on-site.

3. Standard Membrane Module Integration Design: Quick Installation and Simple Operation

The equipment adopts a "factory prefabrication + container integration" mode. All components have completed assembly, commissioning and testing before leaving the factory. On-site deployment only requires 3 steps:

• Connect to an external compressed air source (only power connection is required when an air compressor is integrated as a complete set).

• Connect the nitrogen output pipeline to the operation point.

• Turn on the power and start the control system.

The entire installation cycle is ≤48 hours, which is much faster than traditional on-site installation equipment (15-30 days). The control system adopts a user-friendly PLC touch screen interface, retaining only core functions such as "start, stop, and parameter viewing". On-site operators can operate independently after 1 hour of training.

4. Nitrogen Quality: Stable, Reliable, Clean and Low Dew Point

Membrane separation is a physical process, and the product gas indicators are minimally affected by fluctuations in working conditions:

1. Stable purity: It can stably output nitrogen with a purity of 95%-99.9% (customizable on demand), meeting the requirements of oil and gas inerting (oxygen content <5%), purging and other scenarios.

2. Low dew point guarantee: The standard dew point of the produced nitrogen is ≤-40°C (optional ≤-60°C), completely avoiding corrosion caused by moisture entering pipelines/tanks.

3. High cleanliness: After multi-stage precision filtration (precision 1μm), the nitrogen is oil-free and particle-free, complying with API 551 and other oil and gas industry medium cleanliness specifications.

5. Flexible Capacity Expansion: Adapting to Dynamic Project Requirements

The equipment adopts a modular membrane module design:

• The capacity of a single 20-foot container equipment is 50-200Nm³/h. If the project demand increases, capacity expansion can be achieved by "expanding the number of membrane modules in the container" or "paralleling multiple equipment" (for example, two units in parallel can achieve a capacity of 400Nm³/h).

• Capacity adjustment does not require replacement of the core system, adapting to the characteristics of "short-term operations and phased capacity expansion" of oil and gas projects, avoiding waste caused by equipment idleness or insufficient capacity.

6. Containerized Design: Adapting to the Mobility and Extreme Environments of Oil and Gas Sites

• Convenient transportation: Adopting 20/40-foot standard containers, it can be directly transported to remote oilfields by road and railway without special tools.

• Strong environmental tolerance: The container is equipped with Ex d IIB T4 explosion-proof design, IP54 protection level, and thermal insulation layer, which can adapt to extreme operating environments such as deserts (high temperature of 50°C) and cold regions (low temperature of -30°C).

• Intelligent remote management: The control system supports remote data transmission (optional), and the background can real-time view parameters such as pressure, flow rate and purity, realizing unattended management.

IV. Typical Application Scenarios of Containerized Membrane Nitrogen Generators in the Oil and Gas Industry

1. Drilling Operations: Drilling Fluid Aeration and Wellbore Inerting

In underbalanced drilling, nitrogen needs to be injected into the drilling fluid to reduce density and avoid fracturing the reservoir. At the same time, the oil and gas escaping from the wellbore needs nitrogen inerting to prevent explosion. This equipment can be deployed next to the drilling platform, moving with the drill bit position, stably supplying low dew point nitrogen, and ensuring drilling safety and reservoir protection.

2. Oil and Gas Storage Tanks: Inert Gas Sealing and Displacement

During the loading, unloading and storage of crude oil/natural gas storage tanks, the flammable gas in the tank is prone to forming an explosion zone when mixed with air. Continuous nitrogen injection is required to maintain the oxygen content <5%. This equipment can be deployed near the tank farm, supplying nitrogen continuously 24 hours a day without long-distance pipelines. Its low maintenance feature reduces the inspection workload of the tank farm.

3. Pipeline Construction: Purging and Drying

For newly laid/overhauled oil and gas pipelines, it is necessary to remove air, moisture and impurities in the pipelines. The high-purity and low dew point nitrogen of this equipment can efficiently displace the air in the pipelines and dry the inner wall. The containerized design can move with the construction section, adapting to the phased purging requirements of long-distance pipelines, and improving construction efficiency by more than 30%.

4. Workover Operations: Emergency Safety Protection

During workover operations, residual oil and gas in the wellbore will escape to the operation area, requiring nitrogen inerting of the operation space. This equipment can be quickly transported to the site and deployed within 48 hours, ensuring the safe development of time-sensitive projects such as emergency workover.

V. Value Brought to Customers

Through the innovative design of "membrane separation technology + container integration", this equipment provides a safer, more economical and flexible nitrogen supply solution for the oil and gas industry:

• Cost reduction: The long-term operation cost is 40%-60% lower than that of liquid nitrogen transportation and 20%-30% lower than that of PSA nitrogen generation.

• Efficiency improvement: The deployment cycle is shortened by 80%, adapting to mobile operation scenarios and improving project progress efficiency.

• Safety: Stable low dew point and high-purity nitrogen reduces explosion and corrosion risks, complying with industry safety specifications.

• Simplified management: Low maintenance and easy operation features reduce on-site personnel training and equipment management workload.