Modular Nitrogen Generator

Aluminum alloy module type nitrogen making machine is composed of sever a nitrogen generating modules, using carbon molecular sieve as adsorbent, the principle of pressure adsorption, step-down analysis to absorb oxygen from the air, so as to separate nitrogen automatic equipment.

Pressure Swing Adsorption Nitrogen Generation System

A PSA carbon molecular sieve (CMS) nitrogen generator is equipped with two or more adsorption towers filled with carbon molecular sieves. Clean and dry compressed air is fed into the PSA nitrogen generator and flows through the adsorption towers loaded with CMS. The compressed air passes through the adsorption towers from bottom to top. Leveraging the differential adsorption capacity of molecular sieves for nitrogen, oxygen and other gases under different pressures, components such as oxygen, water and carbon dioxide are adsorbed on the surface of the carbon molecular sieve, while the unadsorbed nitrogen is collected at the outlet as product gas. It flows out from the top of the adsorption tower and enters the nitrogen surge tank. After a certain period, the oxygen adsorbed by the carbon molecular sieve in the adsorption tower reaches saturation and requires regeneration.

Regeneration is achieved by stopping the adsorption process and reducing the pressure of the adsorption tower. The adsorption tower that has completed adsorption is depressurized to the atmosphere after pressure equalization, desorbing the adsorbed oxygen, water, carbon dioxide and other components to finish the regeneration process.

Two or more adsorption towers alternate between adsorption and regeneration, thus producing product nitrogen with stable flow rate and purity. The switching of adsorbers is automatically completed by program-controlled valves regulated by an automatic control system. The performance of a PSA nitrogen generator depends on the performance of components including adsorbers, carbon molecular sieves, process flow, equipment structure and electromagnetic pneumatic valves.

Product characteristics

| TYMKN-1400(Aluminum alloy modular nitrogen generator) | ||||||||||||||

| Model | Air volume | 99.5% | 99.9% | 99.95% | 99.99% | 99.995% | 99.999% | Air inlet /inner wire | Pure gas inlet /inner wire | Length/mm | Width/mm | High/mm | Weight/ton | Process tank |

| TYMKN-3-03 | Nm³/h | 7.98 | 5.80 | 4.93 | 4.06 | 3.48 | 2.61 | DN15 | DN15 | 740 | 500 | 1705 | 0.1 | Built-in |

| Nm³/min | 0.39 | 0.34 | 0.29 | 0.27 | 0.25 | 0.24 | ||||||||

| TYMKN-3-06 | Nm³/h | 15.95 | 11.60 | 9.86 | 8.12 | 6.96 | 5.22 | DN15 | DN15 | 900 | 500 | 1705 | 0.2 | |

| Nm³/min | 0.78 | 0.68 | 0.58 | 0.54 | 0.50 | 0.48 | ||||||||

| TYMKN-3-09 | Nm³/h | 23.93 | 17.40 | 14.79 | 12.18 | 10.44 | 7.83 | DN15 | DN15 | 1063 | 500 | 1705 | 0.3 | |

| Nm³/min | 1.18 | 1.03 | 0.87 | 0.81 | 0.75 | 0.74 | ||||||||

| TYMKN-3-12 | Nm³/h | 31.90 | 23.20 | 19.72 | 16.24 | 13.92 | 10.44 | DN20 | DN15 | 1225 | 500 | 1705 | 0.4 | |

| Nm³/min | 1.57 | 1.36 | 1.16 | 1.10 | 1.00 | 0.96 | ||||||||

| TYMKN-3-15 | Nm³/h | 39.88 | 29.00 | 24.65 | 20.30 | 17.40 | 13.05 | DN20 | DN15 | 1390 | 500 | 1705 | 0.5 | |

| Nm³/min | 1.95 | 1.70 | 1.45 | 1.34 | 1.25 | 1.20 | ||||||||

| TYMKN-3-18 | Nm³/h | 47.85 | 34.80 | 29.58 | 24.36 | 20.88 | 15.66 | DN25 | DN15 | 1550 | 500 | 1705 | 0.6 | |

| Nm³/min | 2.35 | 2.04 | 1.74 | 1.61 | 1.50 | 1.44 | ||||||||

| TYMKN-3-21 | Nm³/h | 55.83 | 40.60 | 34.51 | 28.42 | 24.36 | 18.27 | DN25 | DN15 | 1715 | 500 | 1705 | 0.7 | |

| Nm³/min | 2.75 | 2.39 | 2.03 | 1.88 | 1.75 | 1.68 | ||||||||

| TYMKN-3-24 | Nm³/h | 64.90 | 47.20 | 40.12 | 33.04 | 28.32 | 21.24 | DN25 | DN15 | 1875 | 500 | 1705 | 0.8 | |

| Nm³/min | 3.14 | 2.73 | 2.32 | 2.15 | 2.00 | 1.92 | ||||||||

| TYMKN-3-27 | Nm³/h | 71.78 | 52.20 | 44.37 | 36.54 | 31.32 | 23.49 | DN32 | DN20 | 2035 | 500 | 1705 | 0.9 | |

| Nm³/min | 3.53 | 3.07 | 2.61 | 2.42 | 2.25 | 2.16 | ||||||||

| TYMKN-3-30 | Nm³/h | 80.58 | 58.60 | 49.81 | 41.02 | 35.16 | 26.37 | DN32 | DN20 | 2200 | 500 | 1705 | 1 | |

| Nm³/min | 3.92 | 3.40 | 2.90 | 2.68 | 2.50 | 2.40 | ||||||||

| TYMKN-4-20 | Nm³/h | 79.75 | 58.00 | 49.30 | 40.60 | 34.80 | 26.10 | DN32 | DN20 | 1560 | 660 | 1705 | 0.8 | External |

| Nm³/min | 3.92 | 3.40 | 2.90 | 2.68 | 2.50 | 2.40 | ||||||||

| TYMKN-4-24 | Nm³/h | 95.70 | 69.60 | 59.16 | 48.72 | 41.76 | 31.32 | DN32 | DN25 | 1720 | 660 | 1705 | 0.9 | |

| Nm³/min | 4.70 | 4.08 | 3.48 | 3.22 | 3.00 | 2.87 | ||||||||

| TYMKN-4-38 | Nm³/h | 111.65 | 81.20 | 69.02 | 56.84 | 48.72 | 36.54 | DN32 | DN25 | 1885 | 660 | 1705 | 1 | |

| Nm³/min | 5.50 | 4.78 | 4.06 | 3.88 | 3.50 | 3.36 | ||||||||

| TYMKN-4-32 | Nm³/h | 127.60 | 92.80 | 78.88 | 64.96 | 55.68 | 41.76 | DN32 | DN25 | 2045 | 660 | 1705 | 1.15 | |

| Nm³/min | 6.28 | 5.46 | 4.64 | 4.30 | 4.00 | 3.84 | ||||||||

| TYMKN-4-36 | Nm³/h | 143.55 | 104.40 | 88.74 | 73.08 | 62.64 | 46.98 | DN32 | DN25 | 2210 | 660 | 1705 | 1.3 | |

| Nm³/min | 7.06 | 6.14 | 5.22 | 4.84 | 4.50 | 4.32 | ||||||||

| TYMKN-4-40 | Nm³/h | 159.50 | 116.00 | 98.60 | 81.20 | 69.60 | 52.20 | DN32 | DN25 | 2370 | 660 | 1705 | 1.45 | |

| Nm³/min | 7.84 | 6.82 | 5.80 | 5.37 | 5.00 | 4.79 | ||||||||

| Remarks:1;Adsorption pressure≥0.7MPa,2;When the adsorption is below 0.7MPa,it needs to be converted | ||||||||||||||

| TYMKN-3"represents 3 rows(including process tanks),"TYMKN-4 "represents 4 rows(excluding process tanks),and”-03"represents 3 aluminum alloy towers.MKN stands for Modular Nitrogen Generator. | ||||||||||||||

Working Principle

Pressure swing adsorption air separation for nitrogen production (PSA nitrogen production for short) is an advanced gas separation technology. It uses high-quality carbon molecular sieves as adsorbents and adopts the pressure swing adsorption principle (PSA) at room temperature to separate air and produce high-purity nitrogen.

Oxygen and nitrogen gas molecules have different diffusion rates on the surface of molecular sieves. Smaller-diameter gas molecules (O₂) diffuse faster and enter more micropores of the carbon molecular sieve, while larger-diameter gas molecules (N₂) diffuse slower and enter fewer micropores of the carbon molecular sieve. Utilizing this selective adsorption difference of carbon molecular sieves for nitrogen and oxygen, oxygen is enriched in the adsorption phase and nitrogen in the gas phase in a short time, realizing oxygen-nitrogen separation and obtaining nitrogen as the gas phase enrichment under PSA conditions. The adsorption law of carbon molecular sieves for oxygen can be summarized as: "adsorption at high pressure, desorption at low pressure".

After a certain period, the adsorption of oxygen by the molecular sieve reaches equilibrium. According to the characteristic that the adsorption capacity of carbon molecular sieves for adsorbed gases varies with pressure, the pressure is reduced to desorb oxygen from the carbon molecular sieve, which is the regeneration process. Regeneration can be divided into vacuum regeneration and atmospheric regeneration according to different regeneration pressures. Vacuum regeneration facilitates thorough regeneration of molecular sieves and is easy to obtain high-purity gas, while atmospheric regeneration features a simplified system with high durability and reliability.

A pressure swing adsorption nitrogen generator (PSA nitrogen generator for short) is a nitrogen generation equipment designed and manufactured in accordance with pressure swing adsorption technology. It usually consists of two parallel adsorption towers, and the automatic control system strictly controls the timing sequence according to a specific programmable program to alternately perform pressurized adsorption and depressurized regeneration, completing oxygen-nitrogen separation and obtaining the required high-purity nitrogen.

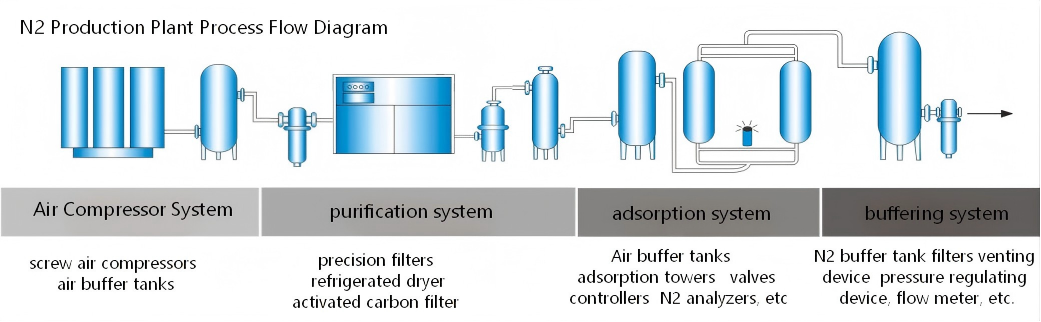

Process Flow

Air Compressor → Air Surge Tank → Grade 9(C) Filter → Refrigerated Dryer → Grade 7(T) Filter → Grade 5(A) Filter → Grade 3 Filter (Activated Carbon Filter) → Modular PSA Nitrogen Generator Main Unit → Nitrogen Surge Tank → Flow Meter → Point of Use

Structure and Nitrogen Output of Modular Nitrogen Generator

The modular nitrogen generator is composed of aluminum alloy modules, usually three or four rows of aluminum alloy modules. The three rows of aluminum alloy modules correspond to Adsorption Tower A, Adsorption Tower B and process tank (built-in) respectively. Its nitrogen output is as follows: Purity 99.5%: Flow rate 7.5–77 Nm³/H; Purity 99.9%: Flow rate 5.5–55 Nm³/H; Purity 99.99%: Flow rate 3.9–39 Nm³/H; Purity 99.999%: Flow rate 2.5–39 Nm³/H.

For higher flow rates, four rows of aluminum alloy modules are adopted, corresponding to two Adsorption Towers A, two Adsorption Towers B respectively, with a separate process tank configured. Its nitrogen output is as follows: Purity 99.5%: Flow rate 77–154 Nm³/H; Purity 99.9%: Flow rate 55–110 Nm³/H; Purity 99.99%: Flow rate 39–80 Nm³/H; Purity 99.999%: Flow rate 25–50 Nm³/H.

Advantages of Modular Nitrogen Generator

1. Compact structure, high efficiency and energy saving

The modular nitrogen generator adopts an advanced process flow design with a simplified structure, which greatly reduces the equipment floor area. Its core lies in replacing traditional carbon steel adsorption towers with light and high-strength aluminum alloy modules, which not only realizes the lightweight of the equipment but also significantly reduces the overall volume. This compact design is particularly suitable for occasions with limited space, such as mobile platforms, small workshops or integrated production lines. In terms of energy consumption, the modular structure, combined with optimized air distribution and control strategies, significantly reduces the overall power consumption of air compression, purification and nitrogen production, thus effectively cutting down the long-term operating costs.

2.High-precision on-line monitoring, easy maintenance

The equipment is equipped with imported high-precision analyzers that can conduct real-time on-line monitoring of nitrogen purity and flow rate, ensuring the stable and reliable quality of the output gas. The analyzers are equipped with automatic calibration and fault diagnosis functions, basically realizing maintenance-free operation and reducing the frequency of manual intervention and subsequent maintenance costs. Users can view all key parameters in real time through the human-machine interface and set purity alarm thresholds as needed, improving the intelligent level of system operation.

3.Advanced molecular sieve filling process, extended service life

The modular nitrogen generator adopts the "blizzard method" for molecular sieve filling. This process fills the molecular sieve uniformly and slowly, avoiding the collision and pulverization of molecular sieve particles caused by high-pressure air flow impact in traditional filling methods. The molecular sieve is evenly distributed in the adsorption tower with high compactness, thereby improving the adsorption efficiency, significantly extending its service life and reducing the replacement frequency and material costs.

4.Flexible mobility, intuitive and convenient operation

This type of equipment is usually designed with a movable structure for flexible deployment between different sites. The operation panel has a clear layout with four key pressure gauges indicating intake pressure, pressure of Adsorption Towers A/B and finished nitrogen pressure respectively, making the operation status clear at a glance. A nitrogen transmitter and flow sensor are integrated in the cabinet, and the data can be centrally displayed through the touch screen and supports remote transmission to the central control system for remote monitoring. An emergency stop button, operation status indicator lights and comprehensive alarm prompts are installed at the lower part of the equipment, further improving the operational safety and emergency response capability.

5.High customization, adaptable to diverse demands

The modular nitrogen generator supports personalized design and configuration according to customers' actual application scenarios, gas volume requirements, site conditions and functional requirements. Common structural forms include skid-mounted, box-type and module-integrated types, and the electrical control system can also flexibly adopt various schemes such as independent electric control cabinets or centralized control cabinets. This high degree of customization ensures that the equipment can be seamlessly connected with users' existing production processes and give full play to its efficiency.

6.Wide range of application fields

With its stable and reliable performance and flexible structural design, the modular nitrogen generator plays an important role in numerous industries. Electronics industry: Inert protection in semiconductor production, circuit board welding and other processes; Food and beverage industry: Application in food packaging, storage and fresh-keeping, and beverage filling; Chemical and pharmaceutical fields: Used as reaction protection gas, material conveying gas or pharmaceutical packaging gas; Metal processing industry: Oxidation protection in heat treatment, brazing, sintering and other processes; Mobile operation scenarios: Temporary nitrogen supply occasions such as oilfield nitrogen injection, ship gas supply and on-site maintenance.