Membrane Nitrogen Generator

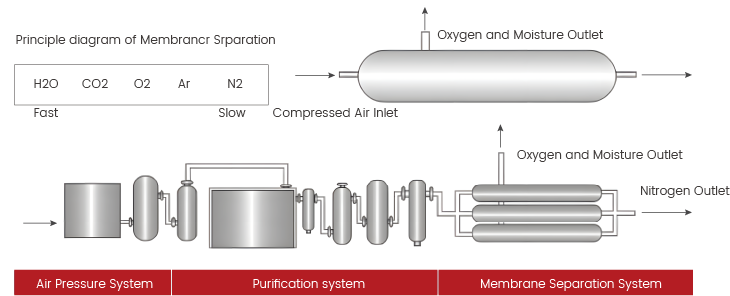

The main principle of membrane separation Nitrogen equipment is selective permeation.Each gas component in the air has its unique permeability and permeability in the polymer film,showing the ability to dissolve and diffuse in each component through the polymer film.According to this characteristic,the gas with faster permeability of polymer membrane can be separated from the slow gas such as nitrogen.

Product characteristics

|  |

Process flow diagram

Product Parameters

| HBFM95 type | ||||

| Model | (Nm3/h) Gas production | (Nm3/min) Air consumption | (mm) Imported nominal diameter DN | DN(mm) Export nominal diameter DN |

| HBFM95-50 | 50 | 2.1 | 32 | 25 |

| HBFM95-60 | 60 | 2.55 | 32 | 25 |

| HBFM95-70 | 70 | 2.9 | 32 | 25 |

| HBFM95-80 | 80 | 3.4 | 40 | 25 |

| HBFM95-100 | 100 | 4.25 | 40 | 25 |

| HBFM95-120 | 120 | 5.1 | 40 | 32 |

| HBFM95-150 | 150 | 6.38 | 50 | 32 |

| HBFM95-180 | 180 | 7.65 | 50 | 40 |

| HBFM95-200 | 200 | 8.5 | 50 | 40 |

| HBFM95-300 | 300 | 12.77 | 65 | 40 |

| HBFM95-400 | 400 | 17 | 65 | 50 |

| HBFM95-500 | 500 | 20.4 | 80 | 50 |

| HBFM95-600 | 600 | 24.5 | 80 | 50 |

| HBFM95-800 | 800 | 24.5 | 100 | 65 |

| HBFM95-1000 | 1000 | 32.6 | 100 | 65 |

| HBFM95-1200 | 1200 | 40.8 | 100 | 80 |

| HBFM95-1500 | 1500 | 61.2 | 125 | 80 |

| HBFM95-2000 | 2000 | 81.6 | 150 | 100 |

| HBFM99 type | ||||

| Model | (Nm3/h) Gas production | (Nm3/min) Air consumption | DN(mm) Imported nominal diameter DN | DN(mm) Export nominal diameter DN |

| HBFM99-15 | 15 | 1.2 | 25 | 25 |

| HBFM99-20 | 20 | 1.6 | 25 | 25 |

| HBFM99-25 | 25 | 2 | 32 | 25 |

| HBFM99-30 | 30 | 2.4 | 32 | 25 |

| HBFM99-50 | 50 | 4 | 40 | 25 |

| HBFM99-60 | 60 | 4.8 | 40 | 25 |

| HBFM99-80 | 80 | 6.4 | 50 | 25 |

| HBFM99-100 | 100 | 8 | 50 | 25 |

| HBFM99-150 | 150 | 12 | 50 | 32 |

| HBFM99-180 | 180 | 14.4 | 65 | 40 |

| HBFM99-200 | 200 | 16 | 65 | 40 |

| HBFM99-250 | 250 | 20 | 65 | 40 |

| HBFM99-300 | 300 | 24 | 80 | 40 |

| HBFM99-350 | 350 | 28 | 80 | 40 |

| HBFM99-400 | 400 | 32 | 100 | 50 |

| HBFM99-450 | 450 | 36 | 100 | 50 |

| HBFM99-500 | 500 | 40 | 100 | 50 |

| HBFM99-600 | 600 | 48 | 100 | 50 |

| HBFM99-800 | 800 | 64 | 150 | 65 |

| HBFM99-1000 | 1000 | 80 | 150 | 65 |

| HBFM99-1200 | 1200 | 96 | 150 | 80 |

| HBFM99-1500 | 1500 | 120 | 200 | 80 |

| HBFM99-2000 | 2000 | 160 | 250 | 100 |

| Note: The above data is based on 0.8Mpa(G)feed air, ambient temperatuer 20℃ , 0 m elevation and 80% relative humidity as design basis. | ||||

Technical Principle

High-Efficiency Purification Based on Gas Separation Membranes

The core principle of the membrane separation nitrogen generation system is to achieve air separation by utilizing the difference in permeation rates of different gas molecules in polymer membrane materials. When pre-treated compressed air enters the membrane module, "fast gas" molecules such as oxygen, carbon dioxide, and water vapor quickly permeate through the membrane wall and are discharged, while "slow gas" molecules such as nitrogen are enriched on the other side of the membrane module, ultimately forming high-purity product nitrogen. This purely physical separation process requires no phase change or chemical reagents, fundamentally ensuring the system's safety and operational stability.

The polymer separation membrane adopted by the system is a hollow fiber membrane filament prepared through a special process. Each membrane filament has a diameter of only tens of micrometers, but its internal surface area is maximized. A single membrane module can integrate millions of membrane filaments to form a large gas separation interface. This structural design greatly increases the contact area between air and the membrane, not only ensuring the nitrogen purification efficiency but also enabling the system to achieve considerable nitrogen generation capacity within a limited volume.

Core Product Features

Comprehensive Advantages from Design to Operation

1. Simple and easy-to-use low-cost nitrogen generation solution

Compared with traditional cryogenic air separation and pressure swing adsorption (PSA) nitrogen generation, the membrane separation nitrogen generation system has a simpler structure. The entire system consists of an air compressor, a pre-treatment system (filter, dryer), a membrane separation module, a nitrogen buffer tank, and a control system, without complex valve switching mechanisms or low-temperature refrigeration units. This design significantly shortens the system's installation and commissioning cycle. Enterprises do not need to equip a professional operation and maintenance team; only regular equipment inspections are required to ensure stable operation. The full life-cycle cost from equipment procurement, installation to daily maintenance is significantly lower than that of similar products.

For small and medium-sized enterprises or scenarios with scattered nitrogen demand, the "plug-and-play" feature of the membrane separation nitrogen generation system is particularly convenient. It only needs to be connected to a compressed air source and set the required nitrogen purity and pressure parameters. The system can operate automatically and continuously produce qualified nitrogen, avoiding problems such as site occupation and leakage risks of liquid nitrogen storage tanks, allowing enterprises to focus more energy on core production links.

2. Low operation and maintenance burden: fewer moving parts, longer stable cycle

The core component of the membrane separation nitrogen generation system—the membrane separation unit—is a static device without moving parts such as frequently starting and stopping valves and compressors, which fundamentally reduces equipment failure points. Although the pre-treatment unit of the system includes components such as filters and dryers, the replacement cycle of related consumables (such as filter elements and adsorbents) is generally more than several thousand hours, and the replacement operation is simple and convenient, which can be completed without professional tools.

According to third-party test data, the mean time between failures (MTBF) of high-quality membrane separation nitrogen generation systems can reach more than 8000 hours, and the annual maintenance time is less than 20 hours, reducing the operation and maintenance workload by about 60% compared with PSA nitrogen generation systems. This advantage is crucial for continuous production enterprises, which can effectively avoid production line shutdowns caused by equipment failures and ensure the smooth progress of production plans.

3. Stable and reliable nitrogen quality: meeting harsh industrial requirements

The nitrogen purity of the membrane separation nitrogen generation system can be flexibly adjusted within the range of 90%-99.5%, and the purity fluctuation range does not exceed ±0.2%, which can stably match the needs of different scenarios such as modified atmosphere preservation in the food industry (requiring more than 98% purity) and pipeline purging in the chemical industry (requiring more than 95% purity).

The nitrogen produced by the system not only has stable purity but also has the characteristics of "low dew point and low impurities". After deep drying and filtration by the pre-treatment unit, the dew point of nitrogen can reach below -40℃ (some high-end models can reach -60℃), the oil content is less than 0.01mg/m³, and the particle content is less than 0.1μm, which fully meets the harsh requirements for gas cleanliness in industries such as food packaging and chemical engineering.

4. Scalable nitrogen generation capacity: matching the growth needs of enterprises

The nitrogen generation capacity of the membrane separation nitrogen generation system has good scalability. When the enterprise's nitrogen demand increases, there is no need to replace the entire system. The production capacity can be increased only by adding the number of membrane modules or paralleling new membrane separation units. This "on-demand expansion" feature allows enterprises to gradually increase equipment investment according to their own development rhythm, avoiding the capital pressure caused by one-time purchase of large-scale equipment.

Application Scenarios

Flexible Adaptation Across Multiple Industries

With its significant advantages, the membrane separation nitrogen generation system has been widely used in multiple industries:

• Food industry: Used for modified atmosphere preservation and packaging filling of food, extending the shelf life of food and maintaining the taste and nutrition of food;

• Chemical industry: Used for pipeline purging, tank inerting, and material transportation protection, avoiding dangers caused by contact between flammable and explosive materials and air;

• Pharmaceutical industry: Used for aseptic filling and freeze-drying protection of medicines, ensuring the quality and safety of medicines;

System Advantages Summary

Comprehensive Enhancement from Cost to Efficiency

Overall, the membrane separation nitrogen generation system provides enterprises with a "low-cost, low operation and maintenance, high stability, high flexibility" nitrogen generation solution:

Cost level: Compared with liquid nitrogen procurement, it can save 30%-50% of gas costs; compared with PSA nitrogen generation systems, it can save 20%-30% of equipment procurement costs and operation and maintenance costs;

Operation and maintenance level: It has a long average time between failures and small maintenance workload, which can significantly reduce the enterprise's operation and maintenance pressure;

Performance level: The nitrogen has stable purity, high cleanliness, and low dew point, which can meet the application needs of most industries;

Flexibility level: It has fast installation, simple operation, and strong scalability, which can match the nitrogen demand of enterprises at different stages.

FAQ

1.Why customer choose us?

Jiangsu Hongbo Gas Equipment Technology Group Co, Ltd. is a professional manufacturer for green gas plant, such as PSA nitrogen generator, VPSA Oxygen generator, Hydrogen generator, gas purification equipment, air compressor etc.. We have more than 20 years experience in producing and exporting those machines and spare parts.

2.Are you a manufacturer or trading company?

Our headquarters is located in Suzhou, China, factory is located in Dongtai, Yancheng City, Jiangsu, China. We have research and develop center, advanced processing equipment, professional technicians, rich experience workers and after-sales team to offer good quality products and good service to our customers. We also can provide you the OEM&ODM service.

3.What's your delivery time?

Generally 10-45 days, if urgently order, pls contact our sales in advance.

4.How long is your PSA nitrogen&VPSA Oxygen generator and air compressor warranty?

One year for the whole machine when the machines leave our factory.

5.How long could your PSA nitrogen, VPSA Oxygen generator air compressor be used?

Generally, more than 10 years.

6.What's payment term?

T/T, L/C, Paypal and etc. Also we could accept USD, RMB, Euro and other currency (Pls contact our sales for more information

7.How about your customer service?

24 hours on-line service available

8.How about your after-sales service?

1. Provide customers with installation and commissioning online instructions.

2. Well-trained engineers available to overseas service

3. World wide agents and after service available