Heated Desiccant Dryer

Working Principle of the Micro-Heat Adsorption Desiccant Dryer

First Half of the Working Cycle of the Micro-Heat Adsorption Desiccant Dryer

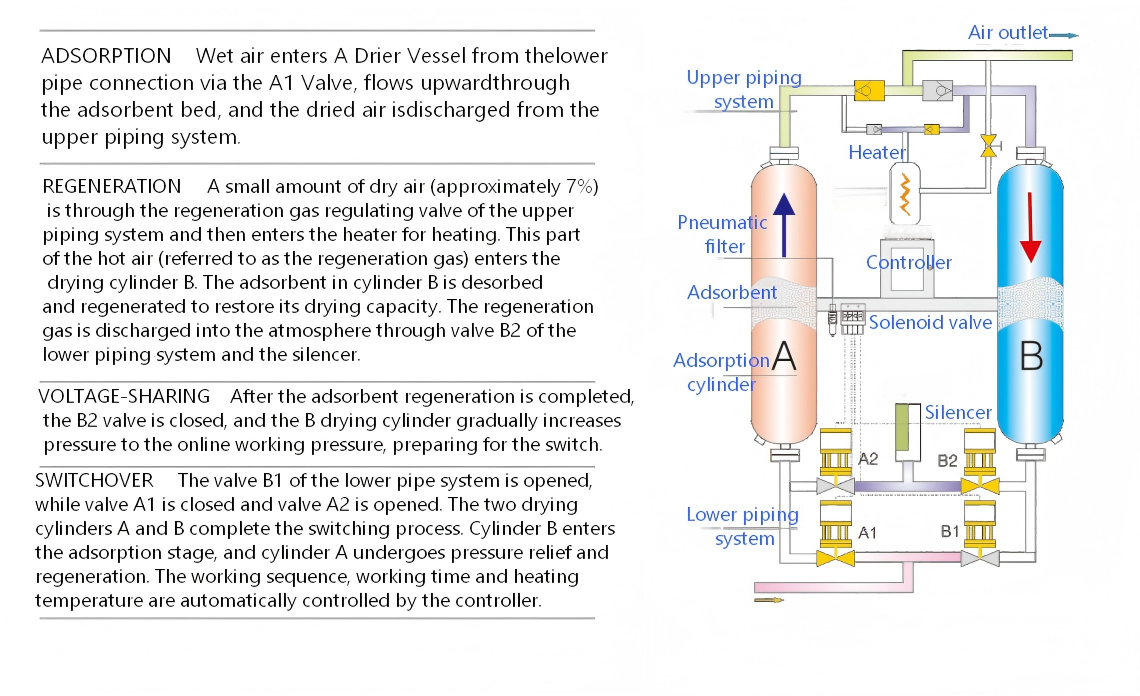

Humid and saturated compressed air is filtered by the pre-installed oil removal filter, then enters Adsorption Tower A through the pneumatic intake valve of Tower A. The moisture in the air is absorbed by the adsorbent inside the tower, turning the air into dry compressed air, which is finally delivered to the air consumption point through the check valve and exhaust port for use. Meanwhile, a small portion (approximately 4~6%) of the dry compressed air is decompressed through the orifice plate, heated to about 150℃ in the heater, and then enters Adsorption Tower B through the check valve. It desorbs moisture from the adsorbent inside Tower B to realize drying and regeneration of the adsorbent, and the moist air is finally discharged to the atmosphere through the exhaust valve and muffler.

Second Half of the Working Cycle of the Micro-Heat Adsorption Desiccant Dryer

Humid and saturated compressed air is filtered by the pre-installed oil removal filter, then enters Adsorption Tower B through the pneumatic intake valve of Tower B. The moisture in the air is absorbed by the adsorbent inside the tower, turning the air into dry compressed air, which is finally delivered to the air consumption point through the check valve and exhaust port for use. Meanwhile, a small portion (approximately 4~6%) of the dry compressed air is decompressed through the orifice plate, heated to about 150℃ in the heater, and then enters Adsorption Tower A through the check valve. It desorbs moisture from the adsorbent inside Tower A to realize drying and regeneration of the adsorbent, and the moist air is finally discharged to the atmosphere through the exhaust valve and muffler.

Differences Between Micro-Heat Adsorption Desiccant Dryers and Heatless Adsorption Desiccant Dryers

Aspect of Difference | Micro-Heat Adsorption Desiccant Dryer | Heatless Adsorption Desiccant Dryer |

Regeneration Principle | Uses an electric heater to heat a small amount of regeneration gas to approximately 90–200°C, then purges the adsorbent under the dual action of heat assistance and pressure change. | Relies on the adiabatic expansion of dry air, which results in extremely low relative humidity and strong moisture absorption capacity to purge the adsorbent. Essentially a Pressure Swing Adsorption (PSA) process. |

Regeneration Air Consumption | Requires electric heating plus a small amount of compressed air; regeneration air consumption is approximately 7% of the compressed air volume. | Regeneration air is supplied by compressed air; regeneration air consumption is approximately 14% of the compressed air volume. |

Pressure Dew Point | Can achieve ≤-20°C to -40°C | Can achieve ≤-40°C to -70°C, with relatively stable performance |

Machine Structure | Includes an additional heater and temperature control system | No heater, resulting in a lighter weight |

invested cost | The heater and temperature control system have a more complex structure and require a higher initial investment. | The selection of the air compressor, dehumidifier and filters at the front stage needs to take into account the issue of high gas consumption. During the selection process, it is necessary to make an appropriate increase in the size. |

Maintenance and upkeep of adsorption type dryers

Maintenance Period (English) | Maintenance Content (English) |

First month & regularly afterwards | Clean or replace the filter element of the control air filter, and replace it regularly thereafter. Purge the exhaust muffler; if the backwash pressure during the regeneration cycle is ≥ 0.035 MPa, replace the muffler. |

Every 3 months | Briefly close the inlet control valve to check for leaks in the air inlet pneumatic valve or regeneration check valve. If air is discharged from the exhaust muffler, it indicates a leak. |

Important Note | The Adsorption Desiccant Dryer contains no lubricants and does not require any lubricating oil. |

Daily | Check the automatic drain valves on the pre-filters and post-filters. |

Weekly | A. Check that switching, regeneration, and pressure boost actions function normally. |

B. Check the opening degree of the regeneration gas valve. | |

C. Check operating conditions: inlet pressure, inlet temperature, and air flow. | |

D. Check if the regeneration muffler is clogged. Excessively high backwash pressure in the regeneration tower indicates the muffler needs replacement. | |

E. Check the pressure drop of the pre-filters and post-filters; replace the filter element if the pressure drop exceeds 0.05 MPa. | |

Monthly | Check the control air filter element and replace it as needed. |

Quarterly (Every 3 Months) | A. Check the pre-filter and post-filter elements for clogging and potential damage; replace as needed. |

B. Use compressed air to blow dust off valves and pneumatic components such as safety valves and solenoid pilot valves. | |

Annual (Every 12 Months) | A. Close the inlet/outlet valves or bypass the dryer, fully depressurize the dryer system, open the adsorbent filling port, and sample the adsorbent for inspection. Replace the adsorbent if it is contaminated with oil or crushed. |

B. Remove and inspect the outlet check valve; repair or replace as necessary. | |

C. Remove and inspect the inlet pneumatic valve and regeneration exhaust valve; clean and replace worn valve seats and seals. | |

D. Check the pneumatic valve cylinders for leaks or worn seals. | |

E. Inspect and repair the solenoid valves in the control air circuit. |