Heatless Desiccant Dryer

Heatless regenerated adsorption dryers in nonstop operation,reliable and efficient they remove moisture from compressed air and depending on the configuration achieve pressure dewpoints as low as -70°C. As high quality allrounders, our compressed air dryers are available for most volume flow and pressure ranges. By the way: our customers have been able to reduce their operating costs significantly, thanks to the low purge air demand and differential pressure.

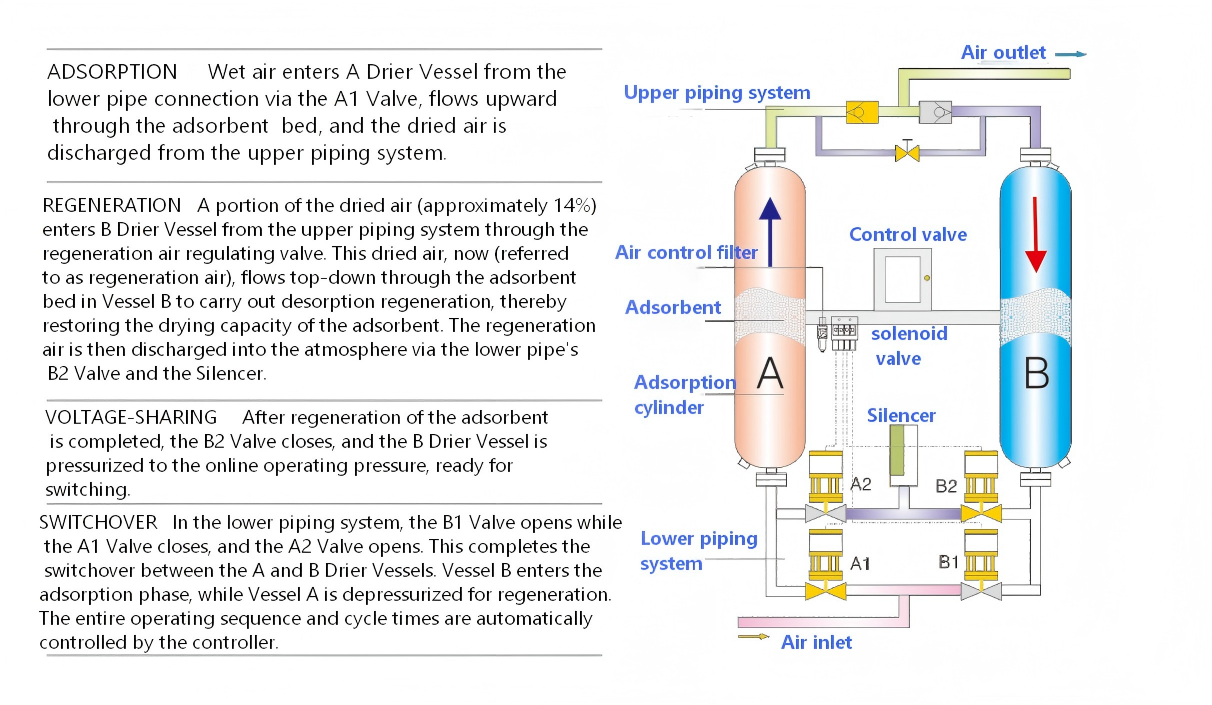

Working Process of Heatless Regenerative Adsorption Dryer

The HONGBO heatless regenerative adsorption dryer relies on the pressure swing adsorption and regeneration cycle technology to achieve deep drying of compressed air. The equipment is equipped with two drying towers filled with special adsorbents, Tower A and Tower B, which adopt an alternating operation mode without the assistance of external heat sources for regeneration during the entire process. During operation, compressed air flows through the two drying towers alternately. When one drying tower is under the high partial pressure condition of the system working pressure, the adsorbent inside the tower fully adsorbs the water vapor in the compressed air to complete the drying process. At the same time, the other drying tower is under the low partial pressure environment of normal atmospheric pressure, where the moisture adsorbed by the adsorbent is rapidly desorbed to realize the regeneration and reduction of the adsorbent. The entire adsorption and regeneration process is automatically switched according to the preset time program, continuously outputting stable and dry compressed air to ensure the continuous and uninterrupted operation of the system.

Product Features of Adsorption Dryer

The tower structure is optimized through professional double precision calculation of thermodynamics and hydraulics, greatly reducing the operating resistance of the tower bed. The contact time between compressed air and desiccant is ≥5 seconds, which fully ensures that the dew point of the outlet finished gas stably meets the process requirements.

Equipped with a 30% desiccant margin design, specially used to compensate for the natural aging loss of desiccant during long-term use, effectively avoiding the attenuation of adsorption performance and ensuring a stable drying effect throughout the process.

Equipped with a large air diffuser, which can make compressed air penetrate the desiccant layer evenly and eliminate channeling and bias flow from the source; equipped with a full electronic programmable controller with a friendly human-machine interface, which automatically and continuously displays the operating conditions of the two towers, with stable and reliable equipment performance and easy operation.

The inner wall of the equipment cylinder adopts a professional cold galvanizing anti-rust treatment process, with excellent anti-corrosion and anti-rust performance, which can achieve 10 years of long-term non-corrosion and extend the overall service life of the equipment.

Selected high-quality adsorbents with large adsorption capacity and stable performance, the service life is more than 5 years under normal working conditions, which greatly reduces the later replacement and maintenance costs.

The air intake and regeneration valve group adopts a 4-valve or 3-valve modular structure design, with excellent valve core sealing performance, stable and reliable operation, strong wear resistance of the valve, and a service life of up to 500,000 actions.

Precisely control the moisture content of the regenerated gas outlet in a subsaturated state, fundamentally avoiding condensation in the muffler and exhaust channel, and ensuring the fault-free continuous operation of the equipment.

Reserved low-load regeneration energy-saving control interface and online dew point detection interface, which can expand energy-saving functions and monitor dew point data in real time according to actual working conditions, adapt to diversified process requirements, and improve the intelligence and energy efficiency of the equipment.

Thermal-free/Micro-thermal (LH) Regenerative Adsorption Dryer Technical Parameters | |||||||

MODEL | Capacity m³/min | Pipe Dia. | Dimension L*W*H (mm) | Power V/HZ | low-grade heat KW/V | Weight (heatless)Kg | (low-grade heat)Kg |

HB0005 | 0.8 | DN15 | 600X350X1500 | 220/50 | 70 | ||

HB0010(LH) | 1.8 | DN20 | 650X450X1500 | 220/50 | 1/220 | 85 | 95 |

HB0020(LH) | 2.8 | DN25 | 700×460X1500 | 220/50 | 2/220 | 105 | 125 |

HB0030(LH) | 3.8 | DN25 | 1000X480X1600 | 220/50 | 2/220 | 220 | 230 |

HB0040(LH) | 5.5 | DN40 | 1000X650X1700 | 220/50 | 3/220 | 250 | 270 |

HB0060(LH) | 6.8 | DN40 | 1000X650X1800 | 220/50 | 3/220 | 270 | 300 |

HB0080(LH) | 8.8 | DN50 | 1100X700X1865 | 220/50 | 4.5/220 | 325 | 355 |

HB0100(LH) | 11.5 | DN50 | 1100X700X2050 | 220/50 | 4.5/220 | 400 | 430 |

HB0120(LH) | 14 | DN65 | 1200X850X2100 | 220/50 | 6.5/380 | 510 | 550 |

HB0150(LH) | 16 | DN65 | 1200X850X2070 | 220/50 | 6.5/380 | 580 | 620 |

HB0200(LH) | 22.8 | DN80 | 1400X1000×2150 | 220/50 | 10/380 | 750 | 800 |

HB0250(LH) | 28.5 | DN80 | 1400X1000×2400 | 220/50 | 10/380 | 850 | 950 |

HB0300(LH) | 35 | DN80 | 1600X1100×2450 | 220/50 | 12/380 | 1100 | 1200 |

HB0400(LH) | 45 | DN100 | 1700X1100×2550 | 220/50 | 15/380 | 1400 | 1600 |

HB0500(LH) | 55 | DN100 | 2100X1100×2700 | 220/50 | 18/380 | 1600 | 1800 |

HB0600(LH) | 65 | DN125 | 2000×1200×2900 | 220/50 | 20/380 | 1800 | 2200 |

HB0800(LH) | 85 | DN150 | 2200X1600×2950 | 220/50 | 25/380 | 2300 | 2700 |

HB1000(LH) | 105 | DN150 | 2600X1600X2950 | 220/50 | 30/380 | 3010 | 3510 |

HB1200(LH) | 120 | DN200 | 2800X1700×2850 | 220/50 | 35/380 | 4000 | 4500 |

HB1600(LH) | 160 | DN200 | 3000X1900×3300 | 220/50 | 40/380 | 6100 | 6600 |

HB2000(LH) | 200 | DN200 | 3500×2200×3300 | 220/50 | 50/380 | 8350 | 8850 |

HB2500(LH) | 250 | DN250 | 3800×2400×3300 | 220/50 | 60/380 | 10300 | 10800 |

HB3000(LH) | 300 | DN300 | 4200×2600×3300 | 220/50 | 70/380 | 12500 | 13000 |

NOTE: HB0005-HB2000, the model is of a double-tower traditional structure; (LH) is a micro-heat adsorption type dryer. | |||||||

Faq

How long is your PSA nitrogen&VPSA Oxygen generator and air compressor warranty?

One year for the whole machine when the machines leave our factory.

How long could your PSA nitrogen, VPSA Oxygen generator air compressor be used?

Generally, more than 10 years.