High Efficiency Compressed Air Filter for Industrial Applications

Why use compressed air filter?

The atmosphere contains water vapour,hydrocarbons and solid particles(about 140 million solid particles per cubic metre of air found in the atmosphere). These impurities are inhaled into the air compressor and then entered to the compressed air network together with residual lubricant.

Failure to treat these contaminants in a timely manner,it will lead to corrosion of pipelines,endangering production equipment, harming tool sensitivity and lifespan, which will eventually affect the products quality.

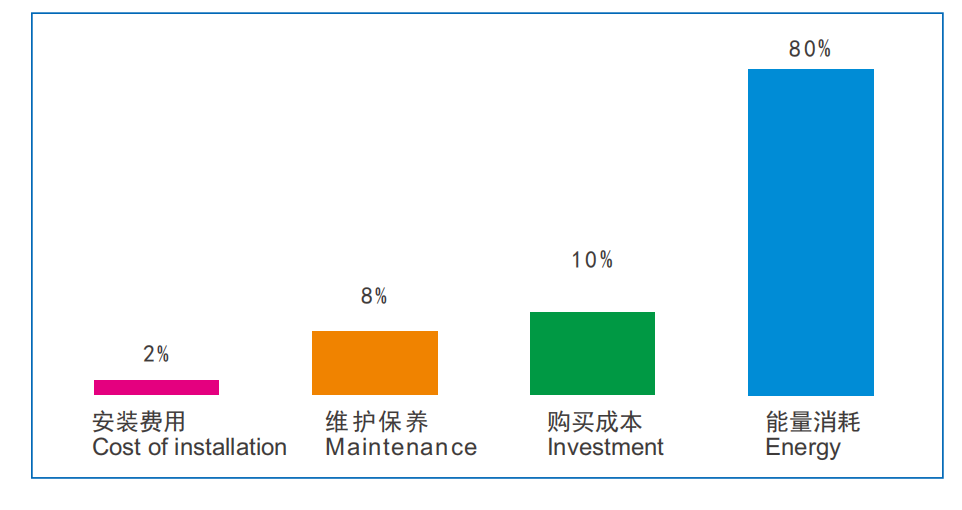

Energy Consumption

For compressed air system, filter resistance is often the key factor of air pressure drop. Under normal operating conditions, the energy consumption of a filter contributes 80 % of the total operating cost, and the air pressure drop of 1 bar is usually equal to 7 %-10 % of air compressor’s energy loss.

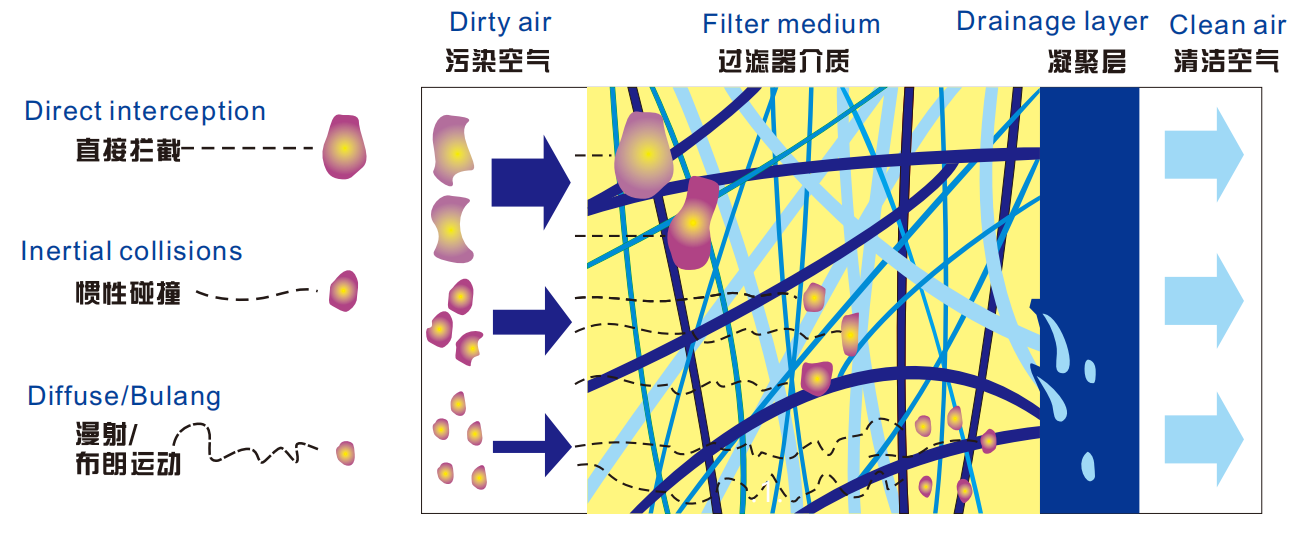

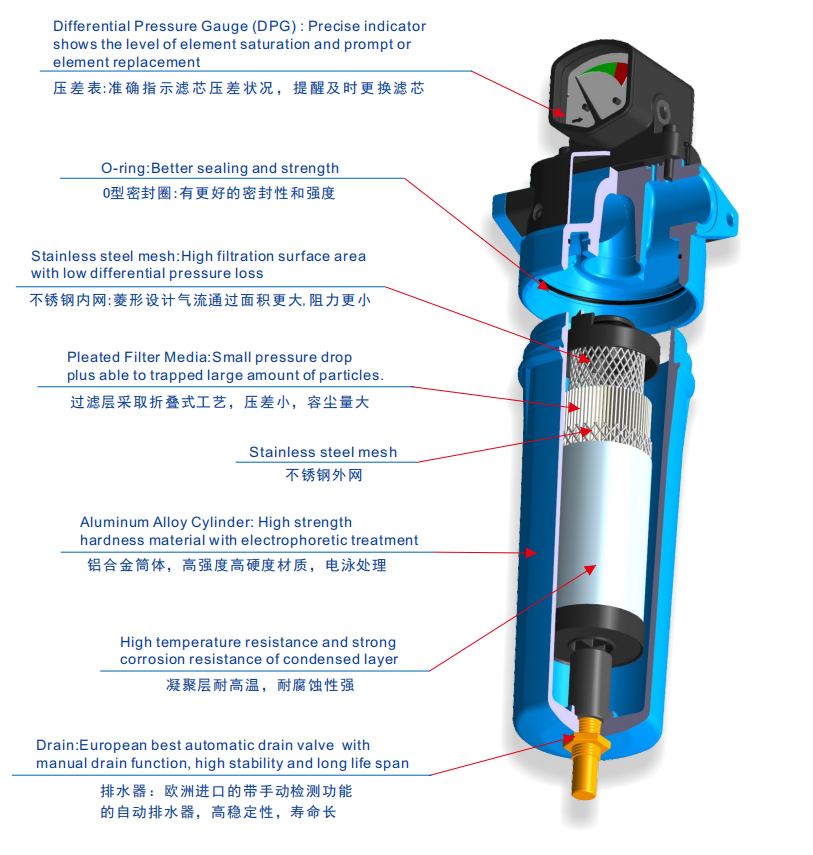

The working principle of compressed air filters

When compressed air enters the filter, flow speed reduce, droplets, large and solid particles will be intercepted directly as they pass through the glass fiber filter. As the smaller diameter droplets and solids particles pass through the filter core, they are captured by inertia collisions and gradually condensed into larger droplets. Once they are close to the filter media, they are adsorbed by the electrostatic force of the glass fiber. The oil and water will then be collected at the bottom of the filter and is discharged through the auto drain. In order to protect the environment,

the oil and water discharged must be collected in a

special container.

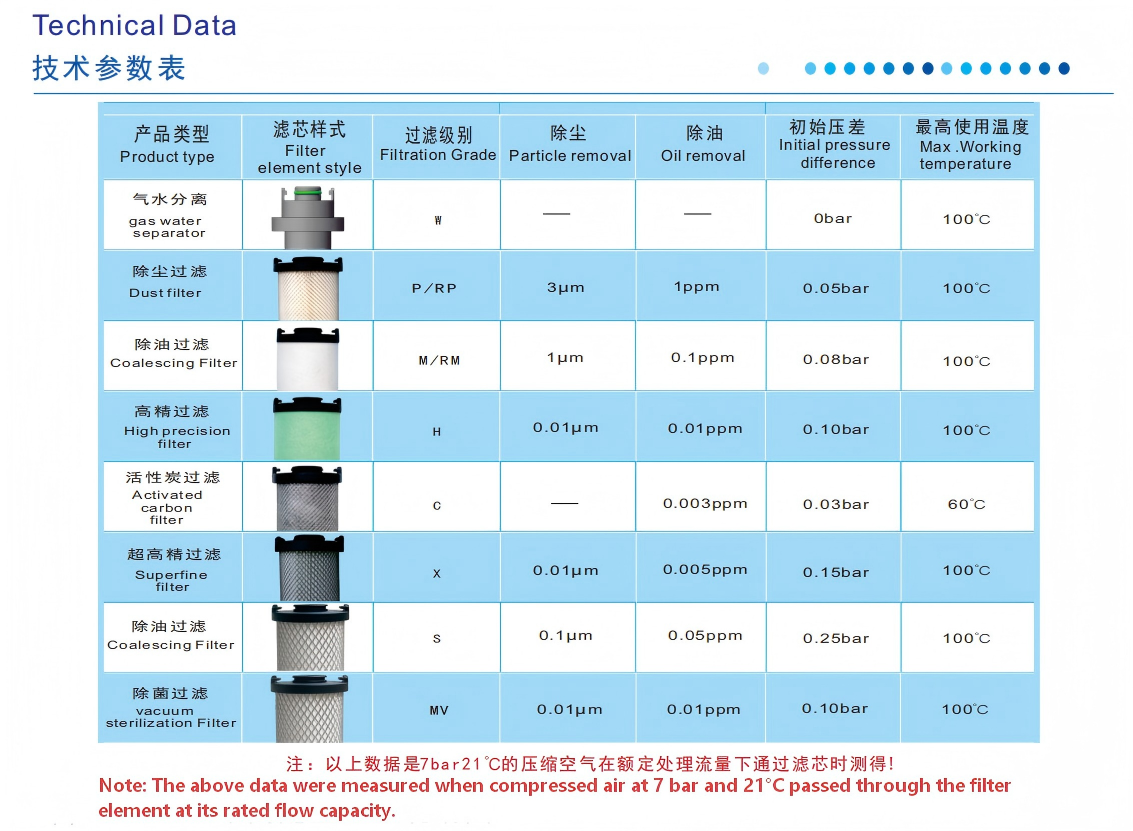

Technical Date

Filter Structure Diagram

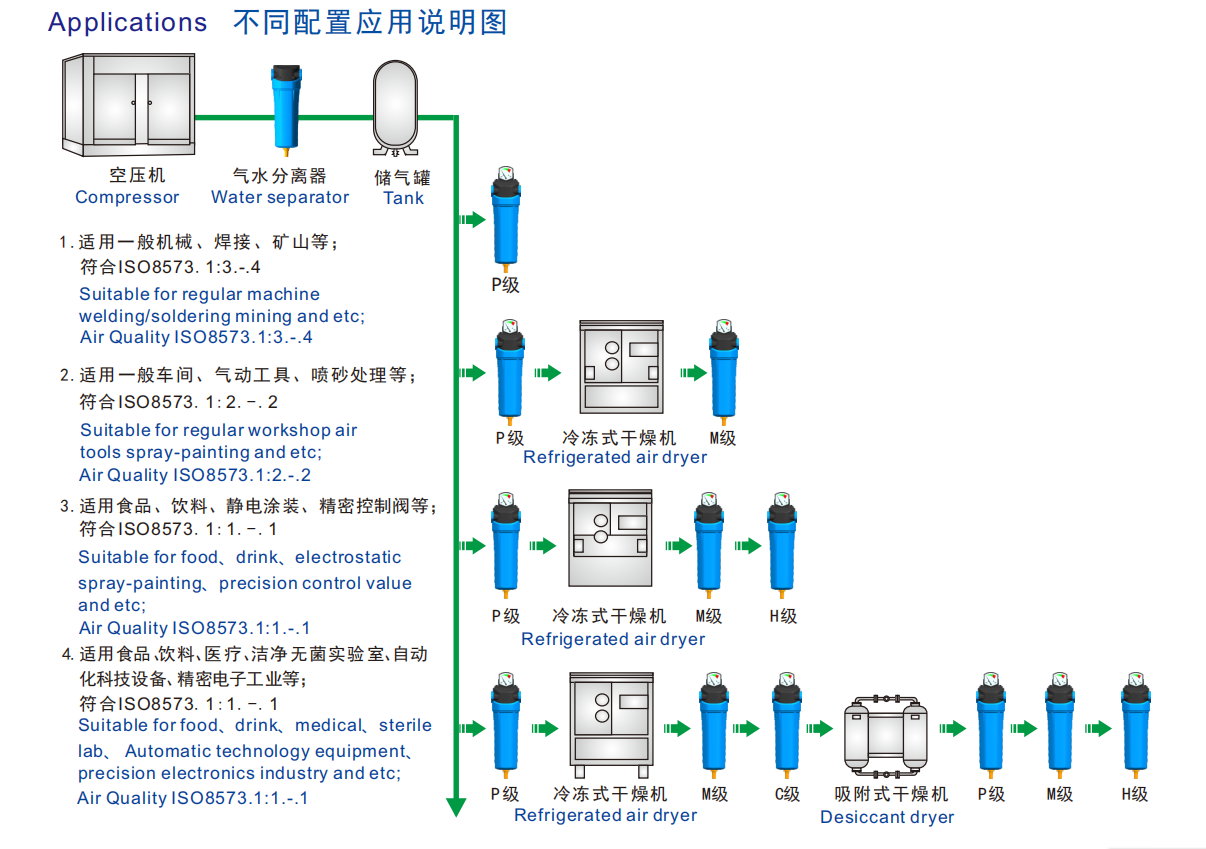

Application

Faq